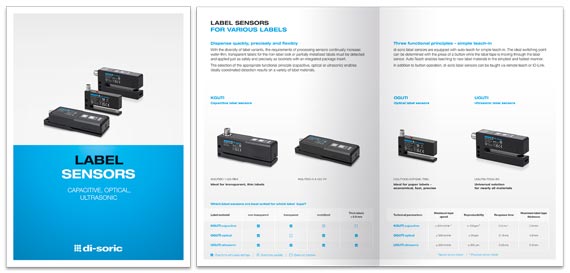

KGUTI-OGUTI-UGUTI

Label sensors

for various labels

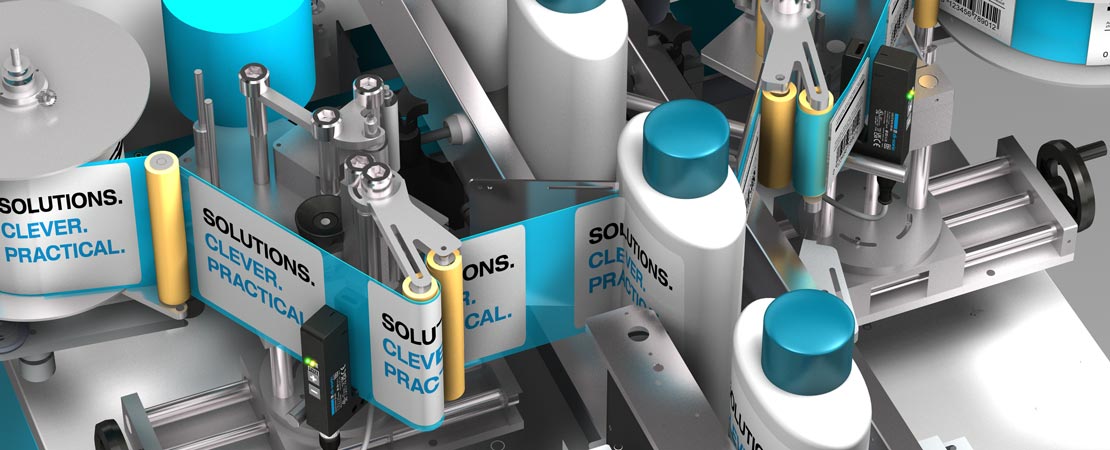

Dispense quickly, precisely and flexibly

With the diversity of label variants, the requirements of processing sensors continually increase: wafer-thin, transparent labels for the non-label look or partially metallized labels must be detected and applied just as safely and precisely as booklets with an integrated package insert.

The selection of the appropriate functional principle (capacitive, optical or ultrasonic) enables ideally coordinated detection results on a variety of label materials.

Three functional principles – simple teach-in

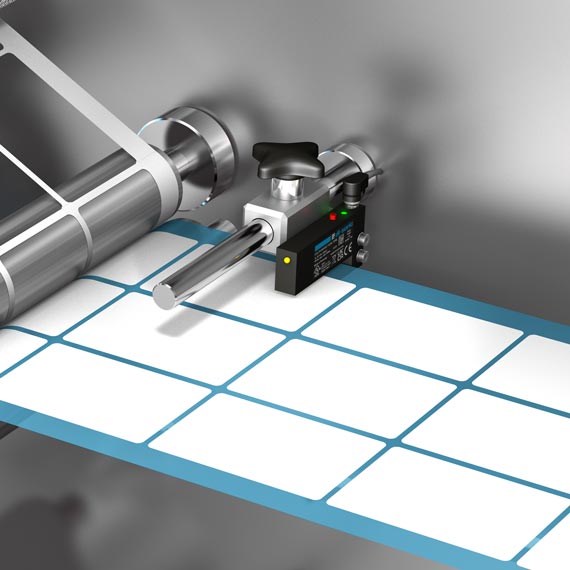

di-soric label sensors are equipped with auto-teach for simple teach-in. The ideal switching point can be determined with the press of a button while the label tape is moving through the label sensor. Auto-Teach enables teaching to new label materials in the simplest and fastest manner.

In addition to button operation, di-soric label sensors can be taught via remote teach or IO-Link.

for which label tape?

with IO-Link

- For the detection of thin, transparent, film and paper labels

- For fast and precise detection of thin and thick paper labels

with IO-Link

- Universally suitable for nearly all label materials

Which label sensors are best suited

for which label tape?

KGUTI

OGUTI

UGUTI

| : Partially suited

| : Not suited

New: Capacitive

label sensors

KGUTI with IO-Link

For the detection of thin, transparent, film and paper labels

Capacitive label sensors are the cost-effective and high-performance solution for position detection of thin, transparent, foil and paper labels. They show their strengths particularly well wherever high tape speeds are required. Using auto-teach, they are taught in to new materials quickly and intuitively.

Precise detection

of thin labels with high reproducibility

Two models available:

- KGUTI80, ideal for wide labels

- KGUTI50, space-saving with 2 fork widths, 1 mm or 0.4 mm for demanding materials

Intuitive Auto-Teach

- Teach-in and fine adjustment via membrane keypad

- 3 LEDs for status, switching output, and diagnosis

Intuitive Auto-Teach

- Teach-in and fine adjustment via membrane keypad

- 3 LEDs for status, switching output, and diagnosis

Push-pull output

- pnp or npn function in one device

Robust, separable metal housing

- Upper and lower portions can be unscrewed for cleaning to remove adhesive residue

- Metal plug connector

Ready for digitization

- IO-Link

- Parallel operation switching output (Pin 2) and IO-Link (Pin 4)

Space-saving

for narrow and wide labels

The right model for every application

Capacitive label sensors from the KGUTI series are available in two different models: KGUTI50 models are flat and may be integrated in a space-saving manner in machines. KGUTI80 models are compatible with a fork depth of 85 mm for wide labels.

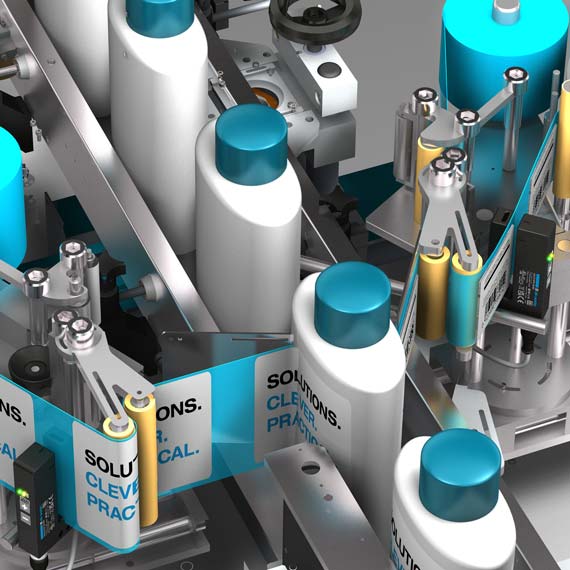

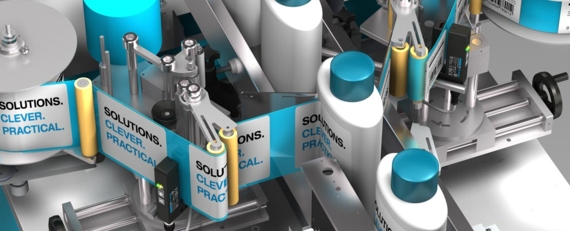

Applications

KGUTI

Optical label sensors

OGUTI

For fast and precise detection of thin and thick paper labels

The cost-effective label sensors from the OGUTI series can be installed near to the dispensing edge due to their compact construction and are suited for paper labels at high tape speeds. The intuitive Auto-Teach function via the operating button enables simple changing of the product during ongoing operation.

High-speed label detection

For tape speeds up to 500 m/min, with short response time

Maximum dispensing precision

- Exact label identification and optimal labeling

- Ideal for detection of paper and non-transparent labels

- High reproducibility: only ±0.05 mm of deviation

Intuitive Auto-Teach

With operating key for simple changing of product during ongoing operation

Installation at the label dispensing edge

Through flat leg

For wide labels

Variants with fork widths up to 100 mm (OGUTI 005/100)

Robust

Metal housing and metal plugs

Large fork width

- For identification of thin and thick labels

- For processing thick booklets with integrated package insert

Platzsparend

für schmale und breite Etiketten

The ideal model for many applications

OGUTI are available in three different models with fork openings of 2 - 5 mm and fork depths of 40 - 100 mm.

Applications

OGUTI

Ultrasonic label sensors

UGUTI

Flexible, fast, precise, simple and robust –

Universally suitable for nearly all label materials

Ultrasonic label sensors do not just detect very thin and transparent foil labels. They also reliably detect metalized labels and provide sufficient clearance for thicker, folded booklets. The innovative dual operating design – alternately configuration and diagnostics via IO-Link or Auto-Teach with manual threshold value adjustment via plus/minus keys – enables quick commissioning of the sensor.

Rugged, compact design with straight

or angled plug connector

- Metal housing and metal connector

- Quick cleaning with blow-out hole

Precise detection

- Response time of just 0.25 ms

- Tape speed of up to 250 m/min

- High reproducibility

Intuitive Auto-Teach

- Teach-in and fine adjustment via membrane keypad

- 3 LEDs for status, switching output, and diagnostics

Operation with process reliability

- Fast, efficient cleaning thanks to large blow-out hole

Ready for digitization

- IO-Link

- Parallel operation switching output (Pin 2)

and IO-Link (Pin 4)

Maximum flexibility

thanks to ultrasound and a fork opening of 6 mm and a fork depth of 70 mm for a wide variety of label material, such as:

- Metallized film labels

- Transparent labels

- Paper labels

- Booklets up to 5.9 mm thickness

- Short labels with length of only 2 mm

Platzsparend

für schmale und breite Etiketten

Variants

UGUTI are available with straight or angled plug connector and a fork opening of 6 mm and fork depth of 70 mm.

Applications

UGUTI

More flexible, transparent and efficient

Production processes with IO-Link

di-soric products and their IO-Link benefits

More information: Click on the symbols

Configuration facilitates commissioning

With their coordinated configuration, di-soric label sensors with IO-Link can be adapted to the application case.

Sensor settings are directly visible in the control and shorten the commissioning times of machines and systems.

Detected switching thresholds for various label materials can be stored in the control for administering format and be repeatedly adjusted.

IO-Link process data with additional benefits

IO-Link process data with additional benefits

IO-Link label sensors from di-soric are designed according to the smart profile as measuring and switching sensors.

The switching state of the sensor and a measured value are transmitted with the cyclical process data.

The measured value depends on the damping of the label material, and specific properties of the carrier tape and label can thereby by assessed quantitatively.

Preventive maintenance through diagnosis

The reliable function of sensors is of the utmost importance in automation.

Label sensors with IO-Link from di-soric signal the functional safety of the teaching process. With IO-Link diagnostic functions on the device status and on maximum and minimum process values, new and difficult materials can be quantitatively assessed during production operation.

Diagnosis supports coordinated service cycles and enables the use of remote maintenance of production systems.

Parallel operation: IO-Link + switching output

The main function of label sensors is the precise, fast positioning of labels. The labeler is controlled directly via a fast switching output.

In addition to and simultaneous to the fast labeling process, important sensor functions can be configured and controlled via IO-Link.

IO-Link enables diagnosis and remote monitoring during ongoing operation.

Sample / Appointment

Download

Order and test samples now!

Test our label sensors and many other solutions free of charge and see for yourself for 28 days.