Maximum precision

Laser fork and angled-

light barriers with IO-Link

Maximum precision

Laser fork and angled-light barriers with IO-Link

The OGUL series laser fork light barriers and the OGLL series laser angled light barriers are particularly suitable for the detection of small parts. Both series have the eye-safe laser class 1.

Ready to run and quickly set up

Fast start-up due to 4 sensor modes and the highly visible laser dot, which enables fast adjustment even in bright environments. The collimated laser red light ensures high accuracy of the switching point over the entire fork width.

Laser fork light barriers

OGUL with IO-Link

When the smallest parts are to be detected

The OGUL series available with fork openings of 30, 50, 80 and 120 mm is the best solution when the goal is process-reliable and fast detection of very small objects down to a size of just 0.03 mm.

With OGUL, the position and alignment of thin wires, drill bits or cannulae can effortlessly be defined down to a (reproducible) accuracy of 0.01 mm.

Benefits of the precise

OGUL Laser / OGUL Laser Stainless steel:

- Fast, reliable detection of the smallest parts with a high functional reserve

- 4 pre-configured sensor modes:

Standard mode is the default – the High Resolution, Speed and Power modes can be selected via IO link - Preferred fields of application:

Detection of very small parts in assembly, handling and packaging technology, as well as quality control - Robust, powder-coated metallic housing or cleanroom-compatible V4A stainless steel housing for areas with strict requirements for hygiene and resistance to cleaning agents – both in the high protection class IP67

- OGUL lasers work reliably and with high process safety in a temperature range between –25 °C and 60 °C

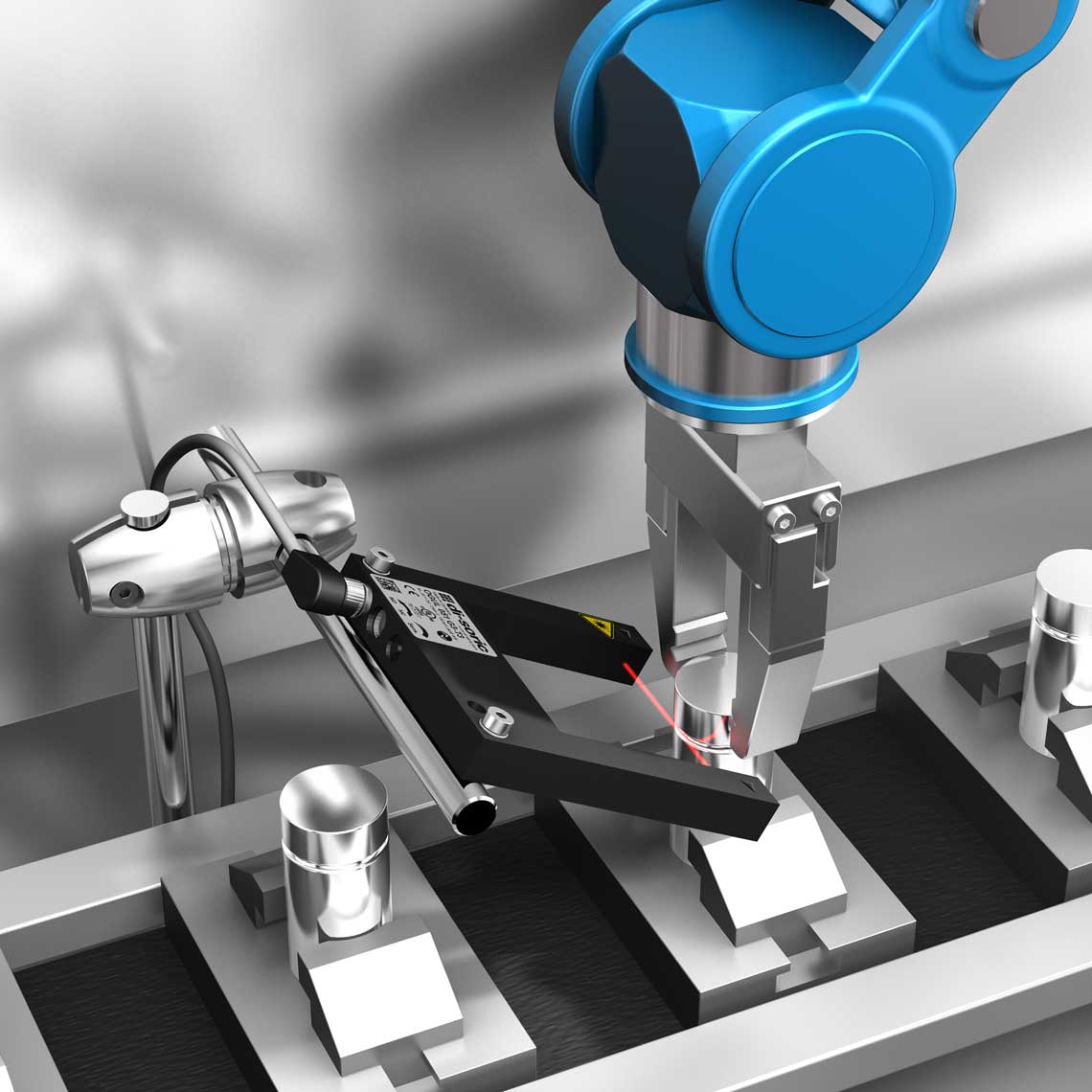

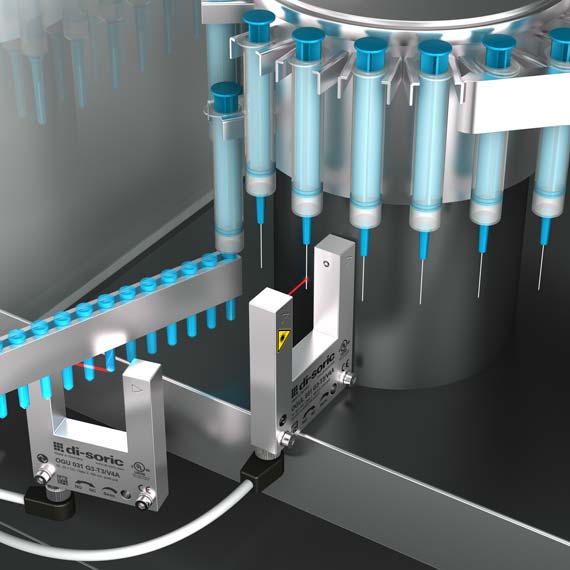

Application examples

OGUL Laser

Laser angled-light barriers

OGLL with IO-Link

Detection of rapid-cycle objects

down to a size of 0.03 mm

The OGLL series is the best solution when the goal is process-reliable and fast detection of very small objects down to a size of just 0.03 mm. With OGLL laser angled light barriers the position and alignment of thin wires, drill bits or cannulae can effortlessly be defined down to a (reproducible) accuracy of 0.01 mm.

Benefits of the precise OGLL Laser:

- Fast, reliable detection of the smallest parts with a high functional reserve

- 4 pre-configured sensor modes:

Standard mode is the default – the High Resolution, Speed and Power modes can be selected via IO link - Preferred fields of application:

Detection of very small parts in assembly, handling and packaging technology, as well as quality control - Robust, powder-coated metallic housing in the high protection class IP67

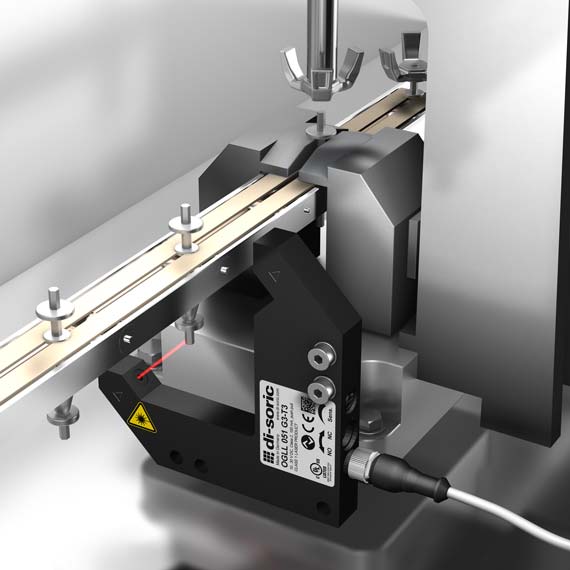

Application example

OGLL

Order and test samples now!

Test our fork and angled light barriers and many other solutions free of charge and see for yourself for 28 days.

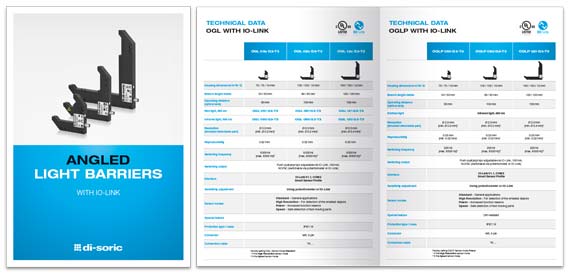

More information

Downloads