di-soric

nVision

The visual development environment

for industrial image processing

We are continuously developing nVision using up-to-date, powerful programming languages like C++ and C#. We consider the extremely diverse range of tasks and requirements that our customers have and integrate them as a solution.

Thanks to nVision, your projects can be implemented better and more quickly, ensuring more efficiency and profitability

nVision combines speed, performance capacity and custom adjustment options to give you the perfect solution. The solution features a pioneering, intuitive and visually attractive user interface and reliable software.

nVision is the result of over 20 years of image processing experience

The versatile software is used for industrial Machine Vision applications as well as scientific image analysis. The outstanding price/performance ratio being offered has already shown its strengths at many companies in a variety of industries. In addition, we provide consultation during the feasibility analysis, undertake project implementation and continue to support you after the project is done by providing service and further developments.

Our services range from visualization in the field of scientific research using interactive image analysis systems to fully automated Machine Vision applications, such as parts inspection, counting, measuring, barcode and matrix code decoding as well as OCR (optical character reading).

- Functions and advantages

- nVision Designer

- nVision Runtime

- The client-server-architecture

- What today's Machine Vision looks like

- Create applications by using a linear sequence

- for image processing and image analysis

- High processing speed

- One program for everything

- Locating, identification, checking, measuring

The easy-to-use image processing software

for industry and science

nVision is the unique and state-of-the-art culmination of 20 years of experience in imaging. nVision is a complete and flexible solution, making it perfect for your application in image processing as well.

Functions

- Live data processing

- Automation of your application

- All pixel calculations either monochromatic or in color

- Barcode and Data Matrix identification

- Completeness check

- Interactive measuring

- Font recognition (OCR, OCV)

- Pattern detection

- Surface inspection

- Position detection and robot guidance

- Printed image control

- Color recognition/color processing

Advantages

- Modern user interface

- Simple, intuitive and personalized operation

- Easy handling

- Top-notch performance

- Wide repertoire of functions

- Ensures that applications are feasible

- Time saving = Time to market is shortened

- Less development time and lower maintenance costs

- Supports a wide variety of cameras

- Easy integration into automated devices

- Individualized service and support

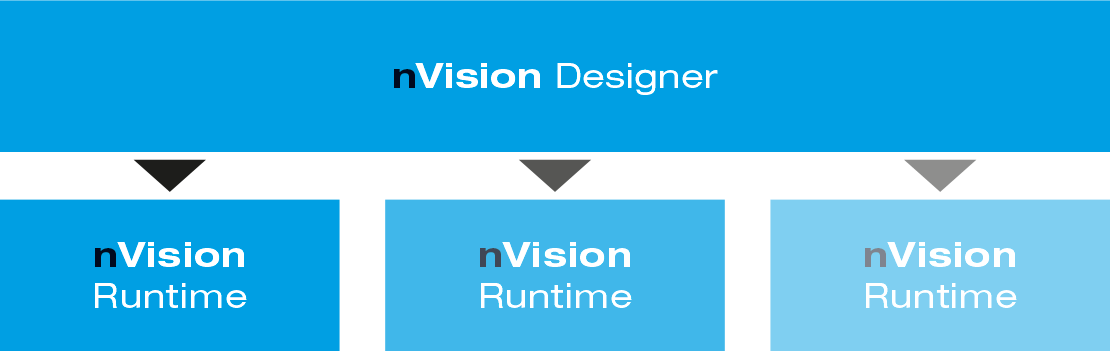

The nVision system:

The components

The software consists of multiple components that communicate with each other over the network.

nVision Designer is immediately visible to the user. nVision Designer can be used to take pictures with cameras, execute image processing commands, combine these instructions to create graphic programs and display the results.

Although nVision Designer may appear to be one cohesive program, it runs its processes in pieces by relying on nVision Runtime. nVision Runtime executes the image processing commands.

nVision Runtime features a modular structure. The only components that need to be available are those that are required by the finished application. For example, it is not necessary to use the OCR and barcode modules if the application is merely taking measurements.

This means that nVision Runtime allows applications to be implemented cost-effectively in pieces.

nVision Designer is the tool that is used to create Machine Vision applications. However, the applications can only be run when nVision Runtime is used.

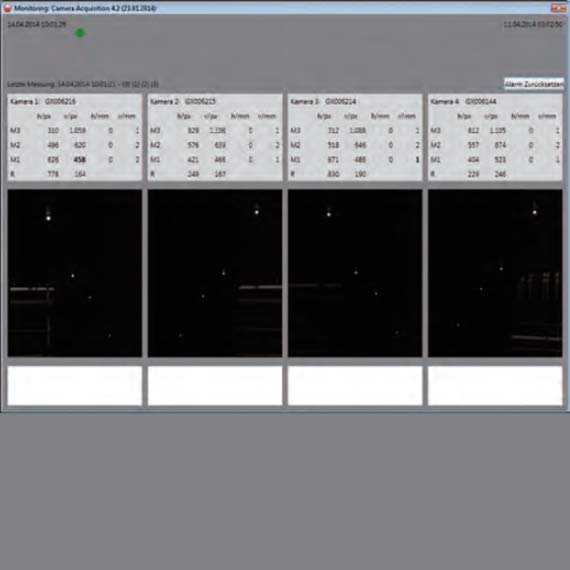

nVision Runtime supports the optional creation of human-machine interfaces. For instance, user interfaces can be created for the machine application.

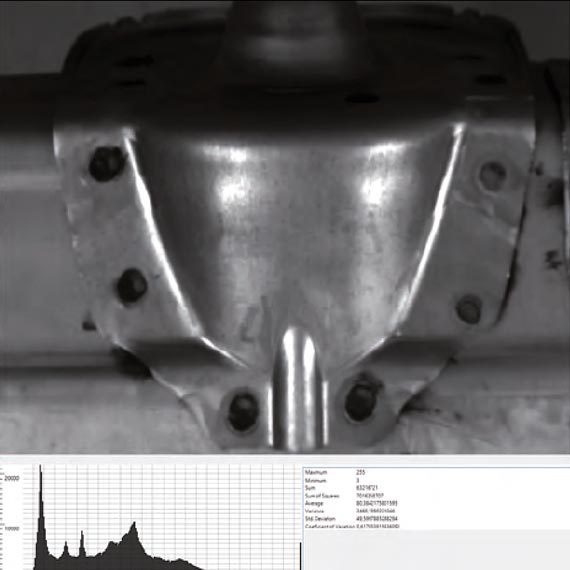

These user interfaces support the display of and interaction with all image types that are relevant in image processing (photos, histograms, profiles, color palettes, geometric objects as well as numeric values, input fields and keys for operation)—even on touch-based devices.

nVISION in

production

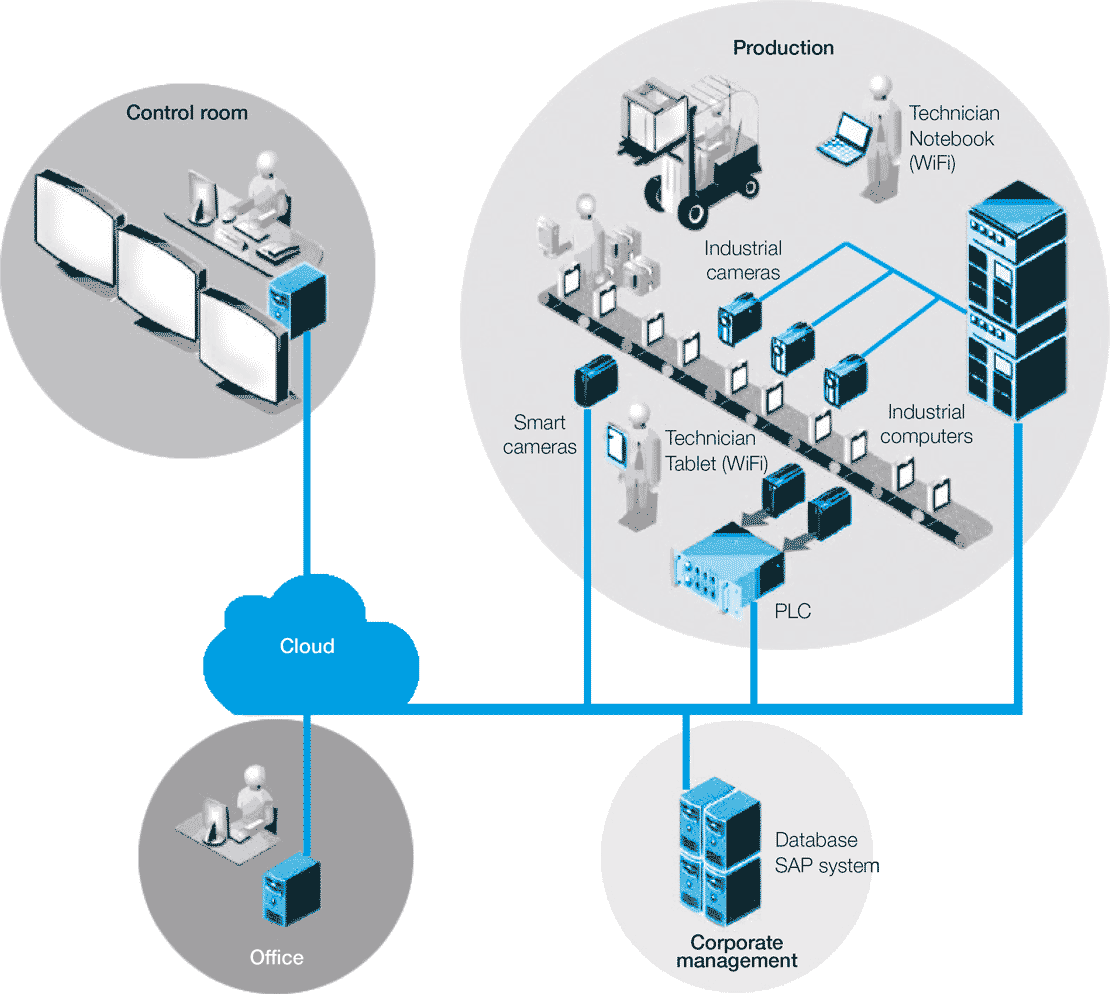

The client-server architecture of nVision Designer and nVision Runtime

nVision Designer can also run on a separate computer from the one running nVision Runtime, turning it into a method of remote operation for nVision Runtime.

Additional applications include configuring an application running on nVision Runtime, not to mention remote monitoring.

The graphic displays a possible scenario for an nVision system:

Multiple cameras are used on the production line. Here, industrial cameras can be connected using industrial computers, each running one or more instances of nVision Runtime. Alternatively, industrial cameras can be operated using embedded computers running an nVision Runtime instance.

It is also possible to use smart cameras (with integrated nVision Runtime).

The computer-camera systems communicate with the machine process over I/O, for instance using a programmable logic controller (PLC).

All computer-camera systems can communicate over the network with both the process control system and a higher-level corporate software such as a database application or a SAP system.

In addition, the computer-camera systems can be operated remotely from an office or control room. This remote operation can be carried out over Ethernet or the cloud.

nVISION

Rapid Development

What today's Machine Vision looks like

nVision already includes everything that you could ever want from state-of-the-art industrial image processing in one package—straightforward operation, visualization, interfaces, and options for expansion.

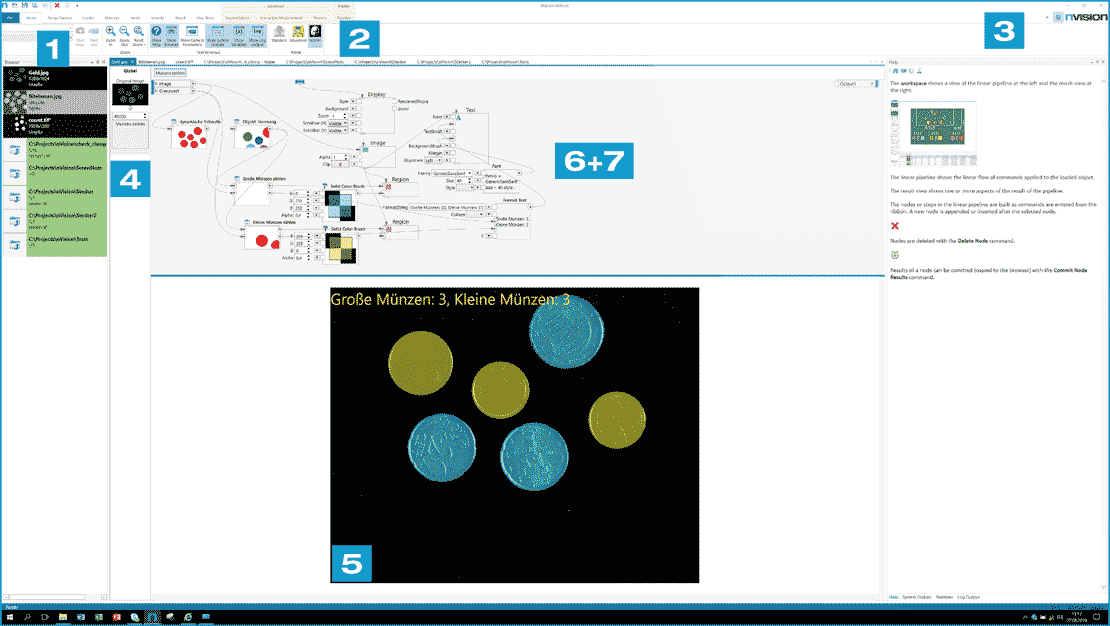

1 Browser

The browser provides a clear overview of images and files with small preview images and the most important information.

2 Ribbon

The important functions are accessed conveniently from the ribbon.

The commands are logically sorted into related groups and are easy to find.

3 Help

Assistance is always available thanks to the integrated handbook.

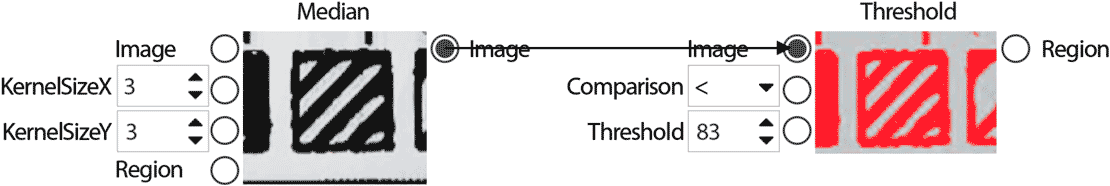

4 Linear sequence

- In the linear sequence, the steps of the application being run are simply queued one after another. The sequence runs step-by-step.

- Small preview images show the results of each step. The live camera image and parameter changes are updated in real time.

5 Display

- In the display window, one or more images or any other data (histograms, profiles, color palettes, data tables, etc.) can be viewed.

- Beyond the predefined views, the user can define custom displays with interactivity (nVision Designer). This is where the Runtime appearance is defined.

6 Pipeline

All processing is carried out in a pipeline for nVision. The pipeline keeps running as long as new data is being fed to it from a source such as a camera.

7 Branched sequence

- Individual steps of the linear sequence may consist of more complex branched sequences.

- The live preview images allow this sequence to be understood easily and intuitively.

nVISION

Linear pipelines

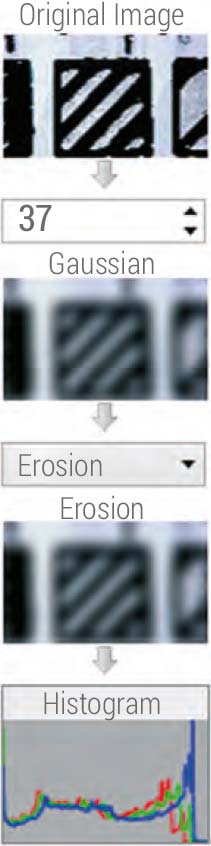

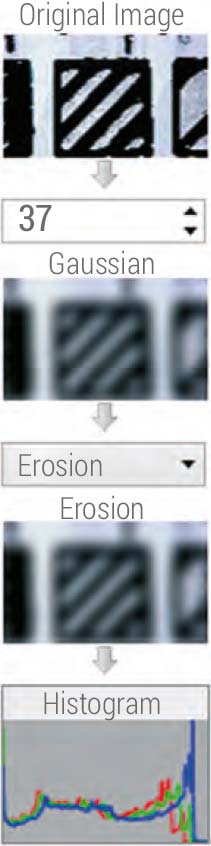

The easiest way to create an application is by using a linear sequence.

All processing is carried out in a pipeline for nVision. The pipeline keeps running as long as new data is being fed to it from a source such as a camera.

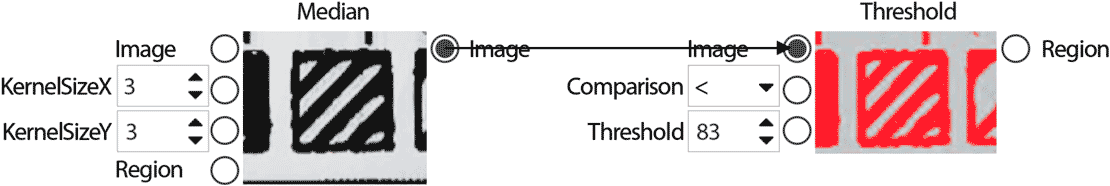

Nodes

- Name, input parameters and a preview of the result are shown.

Input parameters

- A specialized input element makes it possible to edit the most important parameters (text input, spinner, list box, etc.).

Live preview

- The preview has been implemented for all supported data types, including photos, curves, values, graphics, etc. It provides a quick look.

By default, the most recent result from the pipeline has a large display in the display window, but intermediate results can also be viewed in full size with one click.

Automatic connection

- In the linear sequence, the nodes are connected automatically. The data flows from top to bottom.

Predefined nodes

- A large number of predefined nodes are available for selection in order to handle specific tasks.

Sub-programs

- Sub-pipelines can be used to structure applications, implement additional functions or handle specific tasks.

- Sub-pipelines can be nested to any level of depth.

Branched pipelines

- Sub-programs or sub-pipelines are implemented as branched sequences and connected manually.

Live preview

- Just like in the linear sequence, the results of the nodes are displayed as a preview image.

Input parameters

- Here, all parameters are displayed with specialized input elements.

nVISION

Functions

Hundreds of functions for image processing and image analysis

All functions can be linked to each other using simple data flow graphs.

Some of these functions can be seen here.

Image processing

Many simple image processing functions are often necessary for image pre-processing. Arithmetic and logical operators can be used to add, subtract, multiply and divide images and/or constants among each other or link them to each other using logical truth tables.

Filter functions or morphological transformations suppress unwanted image noise or blurs and amplify desired effects such as contrast.

Functions for shading correction reduce the effects of uneven lighting. Color space conversion and classification allows the operations to be used for color image processing as well. Segmentation—the separation of foreground and background—is the basis of particle analysis.

Image analysis

The analysis functions of nVision use images such as line profiles or histograms to determine statistical information. Blob analysis or particle analysis can be used to group related pixel areas into regions. After segmentation and separation into individual objects, several geometric or intensity-based features can be calculated. A filtering or classification function divides the particles into classes.

Pattern matching

The functions for pattern matching are well-suited for finding known objects in images. To do this, a pattern is trained and then searched for in other images. nVision supports various metrics and allows changes to be made to intensity and distortion.

Geometric matching can also tolerate masking and interference.

Optical character recognition

Many industrial applications require that labels be recognized. The character recognition of nVision offers two application modes: Optical character recognition (OCR) and optical character verification (OCV).

Character sets and parameter configuration can be trained in advance to ensure maximum recognition rates, even when image quality is low.

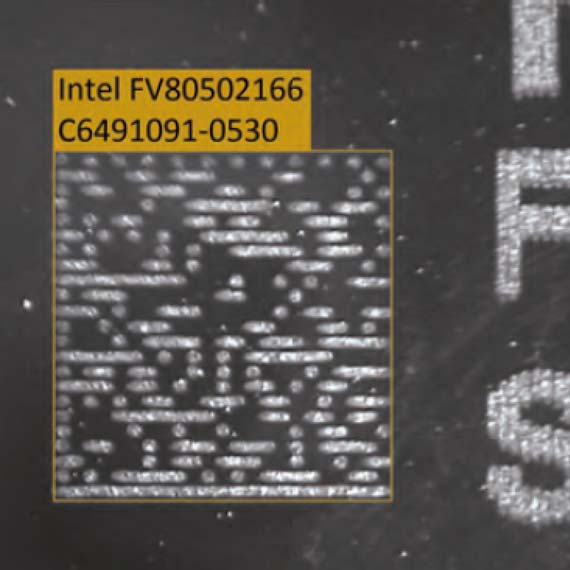

Barcode/matrix code decoding

nVision's barcode and matrix code decoder can locate and decode printed, etched, lasered or punched codes of a variety of one-dimensional or two-dimensional symbologies.

In addition to pure decoding, the print quality of the code can be checked.

Calibration

Tolerances for sensor assembly, lens distortions and freely positioning the camera in space result in a non-linear relationship between pixel coordinates and positions in the real world.

The camera calibration of nVision enables pixel coordinates to be transformed into real coordinates. The function supports correction of non-linear deformations using the lens and angles.

The calibration is enhanced by the addition of the functions for geometric pixel image correction.

Camera support

nVision supports many industrial cameras from various manufacturers and different interface standards (GigE Vision, USB3 Vision, GenlCam).

Measurement

The measurement functions can be used to determine dimensions from the image quantitatively such as distances, angles, areas, line fits and curve fits.

In this process, the positions are determined down to the subpixel level using the grayscale values of the images. Together with the functions for camera calibration, this forms the basis for aligning parts or taking high-precision measurements.

Interaction

Using nVision means that you can both control Optotune LiquidLens modules from the software and control Gardasoft flash controllers.

This means that additional peripheral equipment can be controlled directly from nVision without any additional steps.

Communication

nVision communicates with the outside world through conventional industry standards:

This means that communication over TCP/IP TwinCat is a problem-free option, as is Profinet (using an optional Hilscher module).

nVISION

HighSpeed Machine Vision

High processing speed

nVision features straightforward operation and is performance-optimized through the use of all software and hardware resources.

Experience industrial image processing in real time and benefit directly from extremely high throughput speeds with consistently high precision.

Parallel processing

nVision's image processing functions have been designed to use parallel processing, making them extremely fast.

The parallel processing takes place on three different levels:

- Vectorization at the register level

- Multicore at the image level

- Pipelining at the string level

As a result, nVision is incredibly streamlined.

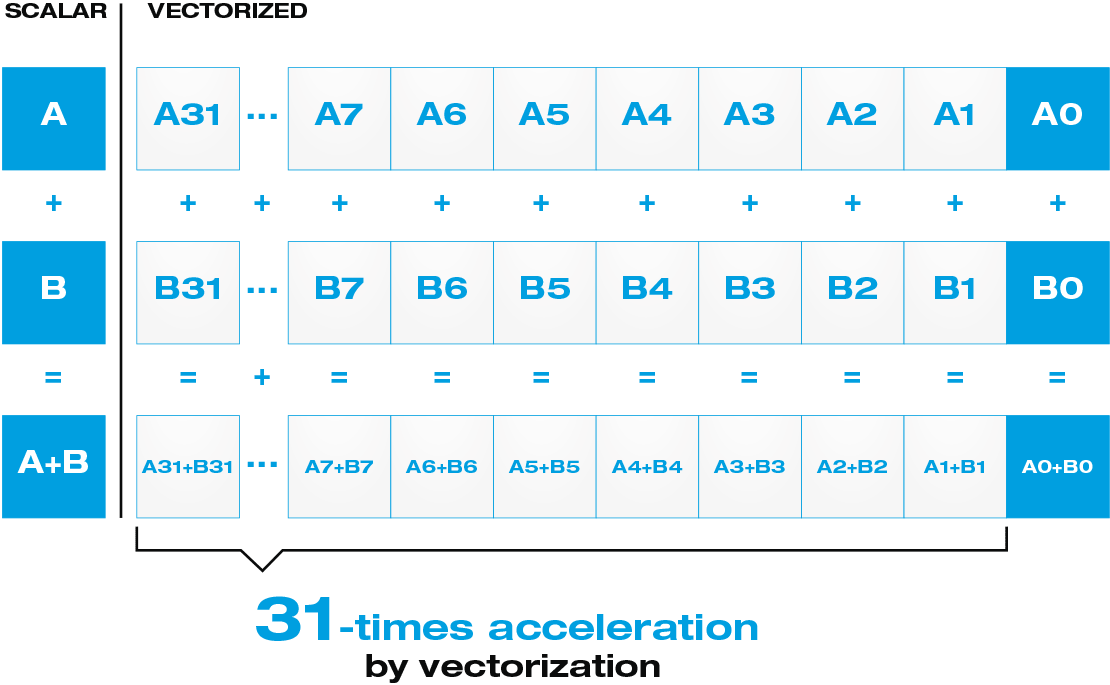

Vectorization

State-of-the-art CPUs have register widths of 64, 128 or 256 bits, while most images are generated at 8 bits per pixel. This means that these CPUs can process 8, 16 or even 32 pixels in parallel in the register in one cycle.

Unfortunately, SIMD programming is extremely costly, which is why there are many providers that do not use it. In nVision, several functions are vectorized.

Multicore

State-of-the-art CPUs usually have at least two, four or more cores. Cores are largely separate CPUs that share the connections to the outside but are contained within a single casing. The cores can carry out different pieces of program code at the same time without slowing each other down.

Many functions in nVision support multi-core parallel processing by dividing large images into smaller portions and distributing those portions among the cores for processing.

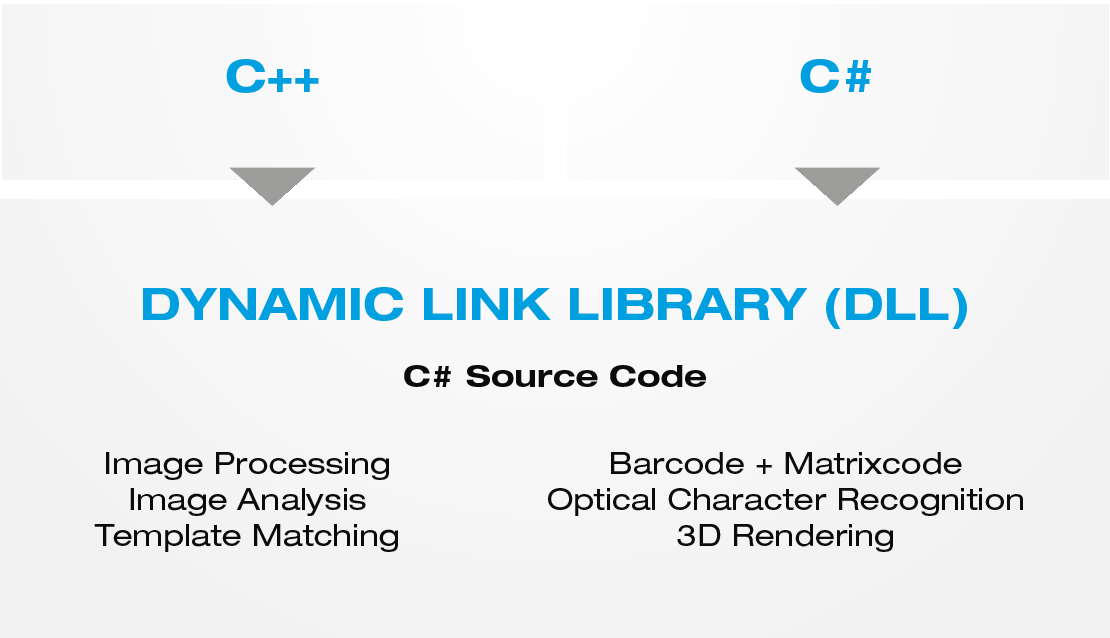

nGI Graphics and image processing library

- nVision also draws its performance capacity from the underlying library for graphics and image processing. nGl is a high-performance library written in C++ for Computer Vision. Your modules can be licensed individually or in combination.

- Connections to various high-level languages are generated using our automatic wrapper functions.

- The libraries are offered in C++ and C# versions for Windows. Additional operating systems and language connections are available on request.

nVISION

Added value

One program for everything

Rely on our many years of expertise in image processing.

If you are unsure whether your application can be run, feel free to get in touch with us. We accept your requests, review them with the required diligence and work with you to find the right path to take.

Feasibility study

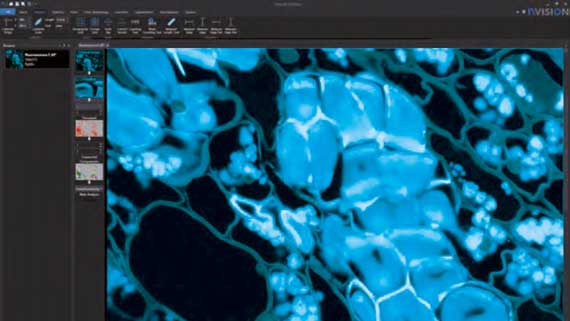

Ergonomics

We take ergonomics seriously. nVision is presented in a clear, consistent interface with a color scheme that is bright and easy to look at. It is ideal for use in an office environment with natural or artificial light.

If you plan on using the software in a dimmed environment, such as a laboratory for fluorescence microscopy, you can switch to a low-contrast view.

Video training

- Using nVision is straightforward and intuitive. After a quick training period, working with the program is quick and easy.

- In addition to the detailed manual, there are online videos in German and English that demonstrate and explain the concepts and work steps.

- You can find the videos on our YouTube channel:

www.youtube.com/di-sorictv

Runtime – Licenses

nVision features a modular structure and allows machine builders and OEMs to embed runtimes into their systems. The only components that have to be available are the ones the user needs in the specific application.

If an application requires part measurement and nothing else, then OCR and barcode modules do not need to be purchased. Classic libraries frequently provide tool sets bundled into packages. It is common for these packages not to include connections to fieldbus interfaces or visualizations for machine builders.

nVision Runtime allows for detailed and cost-effective implementation of applications:

Machine builders or system integrators with image processing tasks purchase and pay for what they actually need and nothing more. di-soric Solutions has drawn upon its many years of expertise in image processing to create nVision, a piece of software that provides its customers in countless areas with tailor-made solutions featuring customer-specific implementation. In both aesthetics and operation, systems are given their very own look and feel that matches the specific company's corporate image. As a result, your image processing is integrated into your system without any gaps—technologically or aesthetically.

nVISION work steps

Locating

Part positioning

It is not always possible to position parts with precision by mechanical means, which means that the image processing software must compensate for the position. Based on the results of the position correction, the part feed can be readjusted or additional inspection tools can be controlled.

The tools for measuring and position correction are able to work more precisely if the camera system with lens are calibrated.

Locating register marks

Aligning parts

Part recognition: fast and very precise in the subpixel range

Edge measurement

This process can be used to detect parts with well-defined, straight edges very quickly. The edge position is determined and then used to calculate the horizontal and vertical displacement and rotation. The tools work accurately down to the subpixel level.

If the optical system is dimensioned optimally and with the right calibration, accuracies better than 1/10 of a pixel can be achieved.

Template matching

Pattern or template matching is better suited for complex parts with irregular forms and difficult color or brightness compositions.

In addition to the conventional correlation method, the processes also offer various similarity measurements that are tailor-made to meet various requirements. The tools support detection of the movement and rotation of the objects.

Similarity measurements

- Difference:

Various difference-based measurements offer extremely fast matching. - Correlation:

Correlation is usually the method of choice for robust pattern matching when brightness and contrast levels vary. - Geometric matching:

Compared to the correlation method, geometric matching is resistant to masking and interference.

CAD

- Template matching tools can also use drawing data from CAD systems.

- Supported formats are DXF (Autocad Drawing Exchange Format) and GEO (laser cutting format from Trumpf) This allows drawing files to be compared to physical objects.

Identification

Tracking parts

Tracking parts is a core Machine Vision task. It requires markings to be recognized on parts, text to be provided in plain text and barcodes or matrix codes to be decoded.

Barcode and matrix code decoding

Optical character recognition (OCR)

Pattern matching: fast and reliable recognition

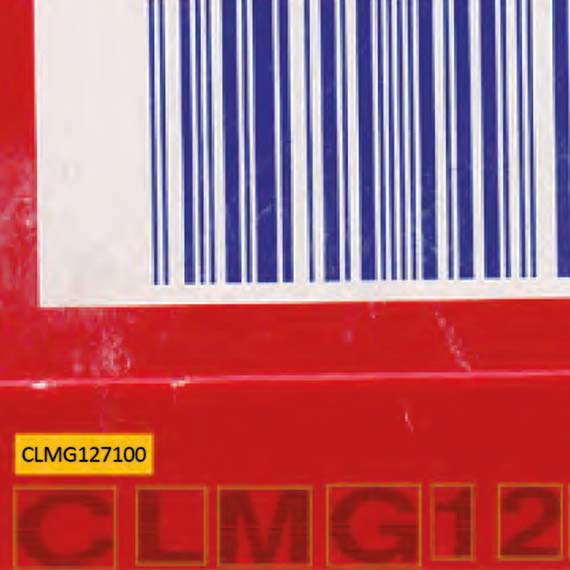

Barcodes

Barcodes are used for product identification. They store information in a series of lines and spaces and can be read easily.

nVision can read barcodes of any size, in any position and in various lighting conditions. In addition, the print quality of the codes can be verified (grading).

Matrix codes

Matrix codes are widely used in many industries for tracking parts. They encode large data blocks on a very small print area, allowing them to serve as a replacement for barcodes in certain cases.

Robust decoding is also difficult due to the range of methods (printing, laser, etching).

The printing process itself must also be tested often (grading).

OCR

In addition to barcodes and matrix codes, products are also marked with readable text. This allows information to be printed on the product such as production or expiration dates or batch numbers on the product.

These pieces of text must be read automatically by cameras. To ensure optimal reading performance, the OCR function can be trained to specific character sets and character patterns.

A set of predefined standard character sets is provided with nVision. In addition, there is a program for training specific fonts for the application in question.

Symbologies

Our software supports the following symbologies:

1D:

- Codabar

- Code 2/5

- Code 32

- Code 39

- Code 93

- Code 128

- Databar

- EAN

- Pharmacode

- PZN

- MSI

- Telepen

- UPC

2D:

- Data Matrix

- QR Code

Checking

Checking parts

Image processing allows a large number of properties to be checked:

Completeness, dimensional accuracy, color, surface quality.

nVision allows you to increase your production quality standards effortlessly.

Print quality of barcodes and matrix codes

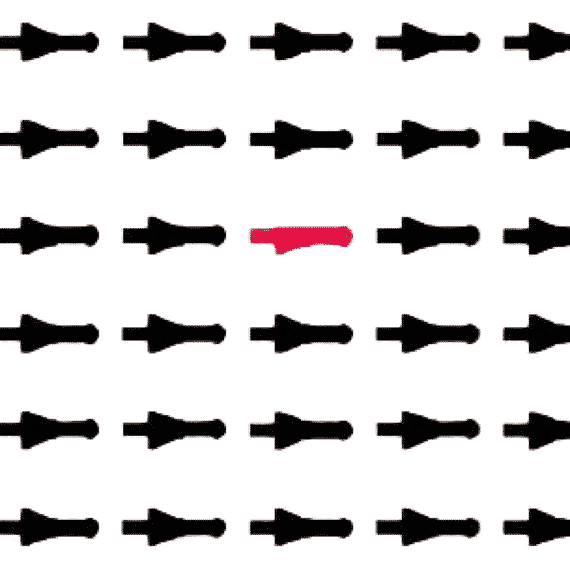

Surface inspection: nVision counts and classifies

Legibility of labels

Errors such as scratches, holes, cavities, breaks

Completeness check

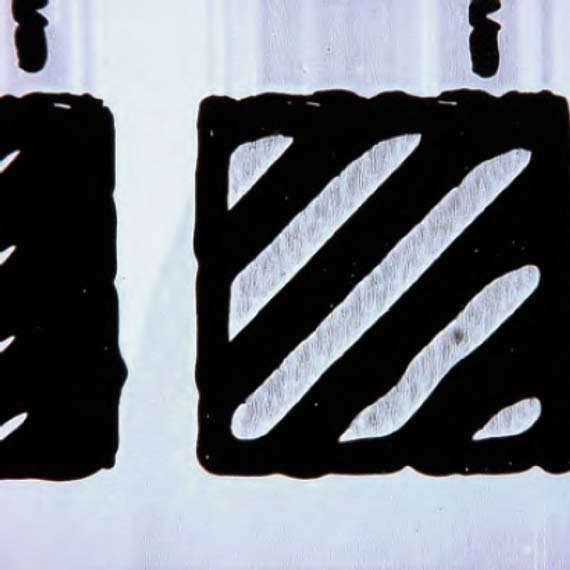

Surface inspection

Scratches, holes, breaks, cavities, dirt—there are many defects that impede the quality of surfaces. Different types of defects often require different lighting (incident light, transmitted light, bright field, dark field) and they can often be detected only when different types of lighting are combined.

nVision has tools for surface inspection, such as multi-channel blob analysis, that allow the software to detect defects and classify types of defects easily.

Grading

The barcode and matrix code tools in nVision can determine the print quality of codes in accordance with ISO/IEC 15415, 15416 or AIM DPM 1-2006.

This allows you to ensure that you codes can always be read accurately.

The OCV functions also allow you to check the quality of labels.

Completeness

In many production steps, it is important that parts be checked for completeness.

This can be done using various nVision tools, e.g. template matching, color matching, edge measuring and decoding codes or text.

Measuring

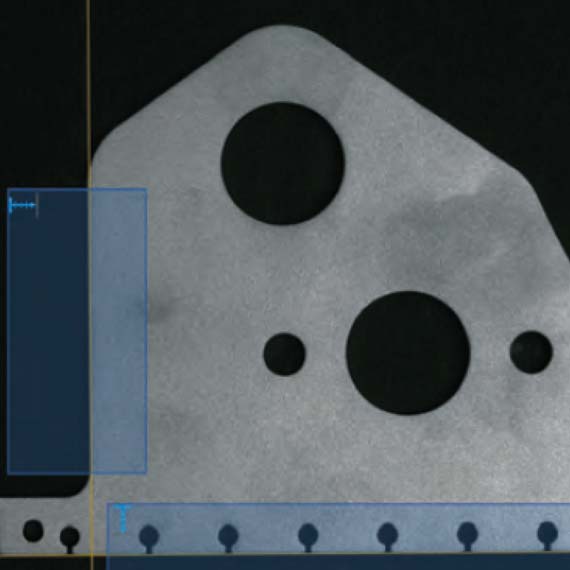

Calibrated Machine Vision systems measure lengths, angles and areas in 2D and 3D without making contact.

Thanks to our algorithms, which are precise down to a fraction of a pixel, you can reach the required level of precision and reduce tolerances in your production. In addition to the geometric variables, the image processing function can also measure densitometric values that depend on brightness or color.

Calibrated measurements

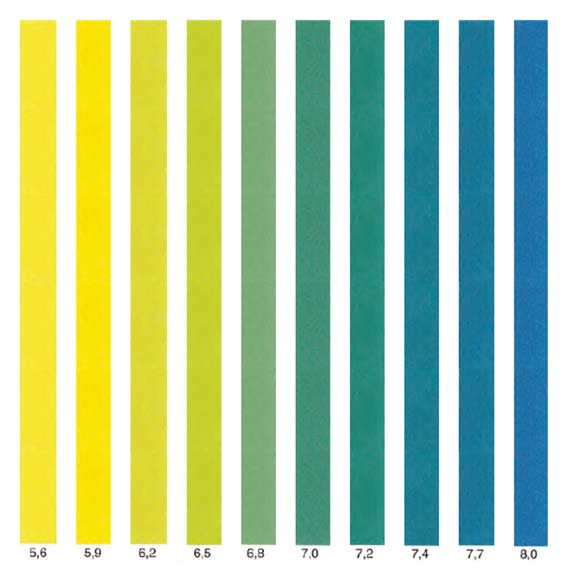

Measurement of intensity in the grayscale and color image

Geometrical measurement

Dimensional measurement

You can achieve high-precision results using our telecentric lens and telecentric lighting coupled with the precise measurement algorithms of nVision.

The desired measurement (position, length, angle, edge position, area, etc.) is defined within a search range and evaluated precisely. The measurement results can be combined and can be either exported as a report or processed to make a good/bad statement.

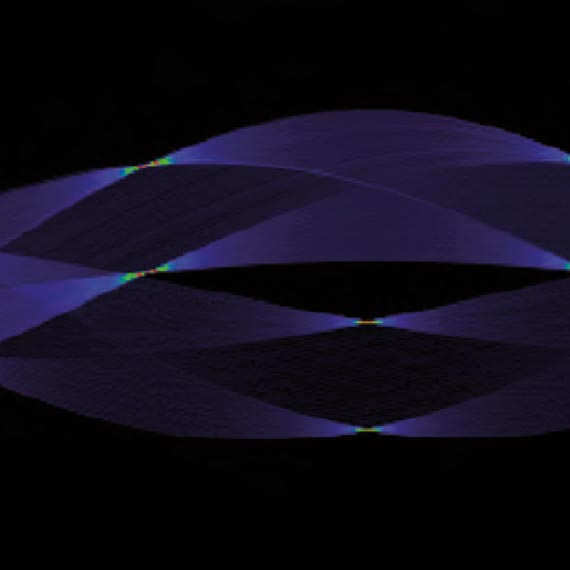

Deformation monitoring

The movement or deformation of large or small parts can be measured and checked by the image processing function in real time.

The real-time monitoring can be used for objects ranging all the way from small machine parts to large building structures.

Calibration

Even when low-distortion lenses are being used, camera calibration is absolutely necessary if you want to take measurements with maximum accuracy.

Calibration is a way of compensating for the distortion of the lens-camera system so that the sub-pixel algorithms can deliver results at the highest possible level of accuracy.

Density measurement

The optical density is a measurement of product quality in some production processes, for example, when applying coatings.

When certain lighting is used, the coating thickness is the result of different grayscale values or colors that can be measured by the image processing function.

You can use image processing to keep the tolerances of your production processes within strict limits.

Appointment

Download

Make an appointment now!

Benefit from our expert knowledge and make an appointment for a consultation – by phone, video conference or on site.