Labeling

Technology

For the production, dispensing and inspection of labels, di-soric offers a wide variety of solutions – each adequate for the individual requirements of the application.

A variety of materials, different sizes and high speeds pose special challenges for control and monitoring in labeling technology. This requires compact designs and high availability of sensors and vision sensors.

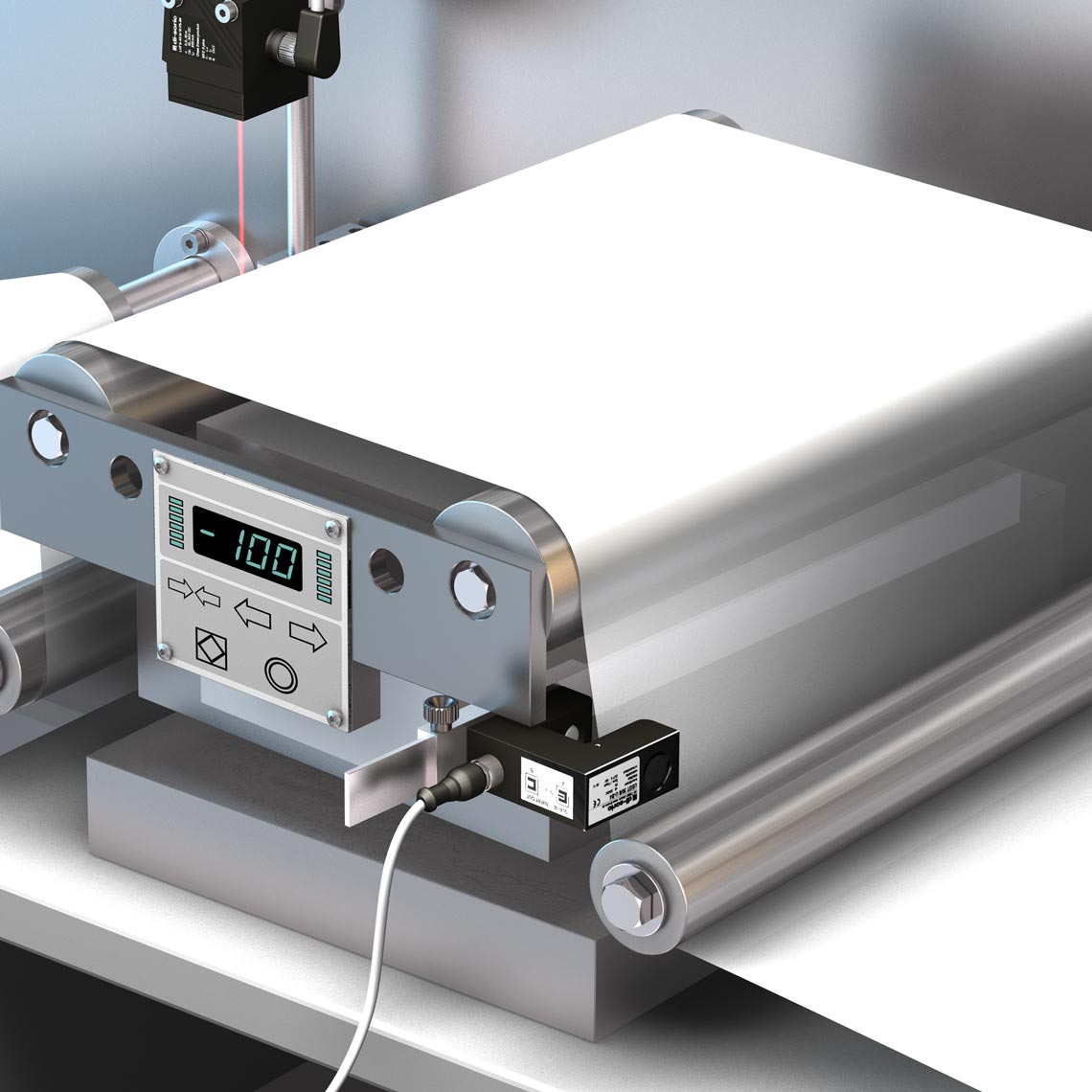

- Roller diameter check

- Loop control system

- Web edge control

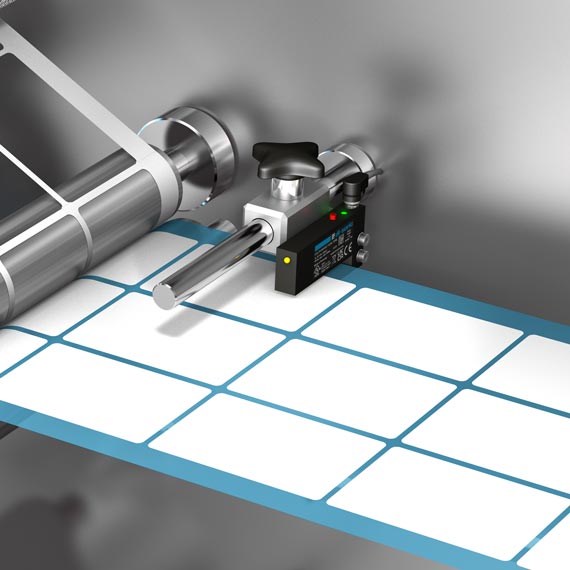

- Punching and identifying labels

- Identifying and positioning labels

- Label sensors

Supporting sensors:

- Detecting empty label coil

- Detecting end position at guide roller

- Triggering labeling

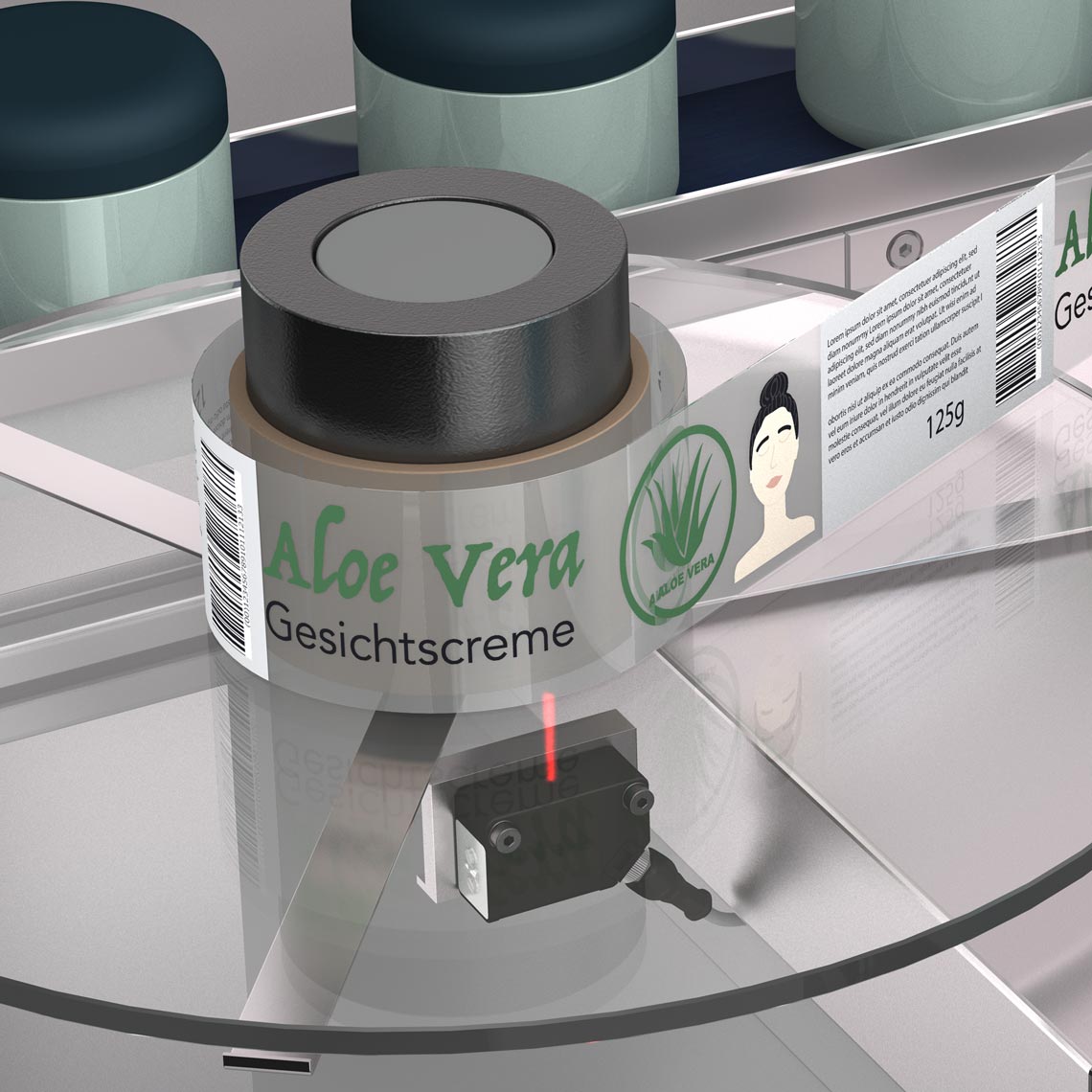

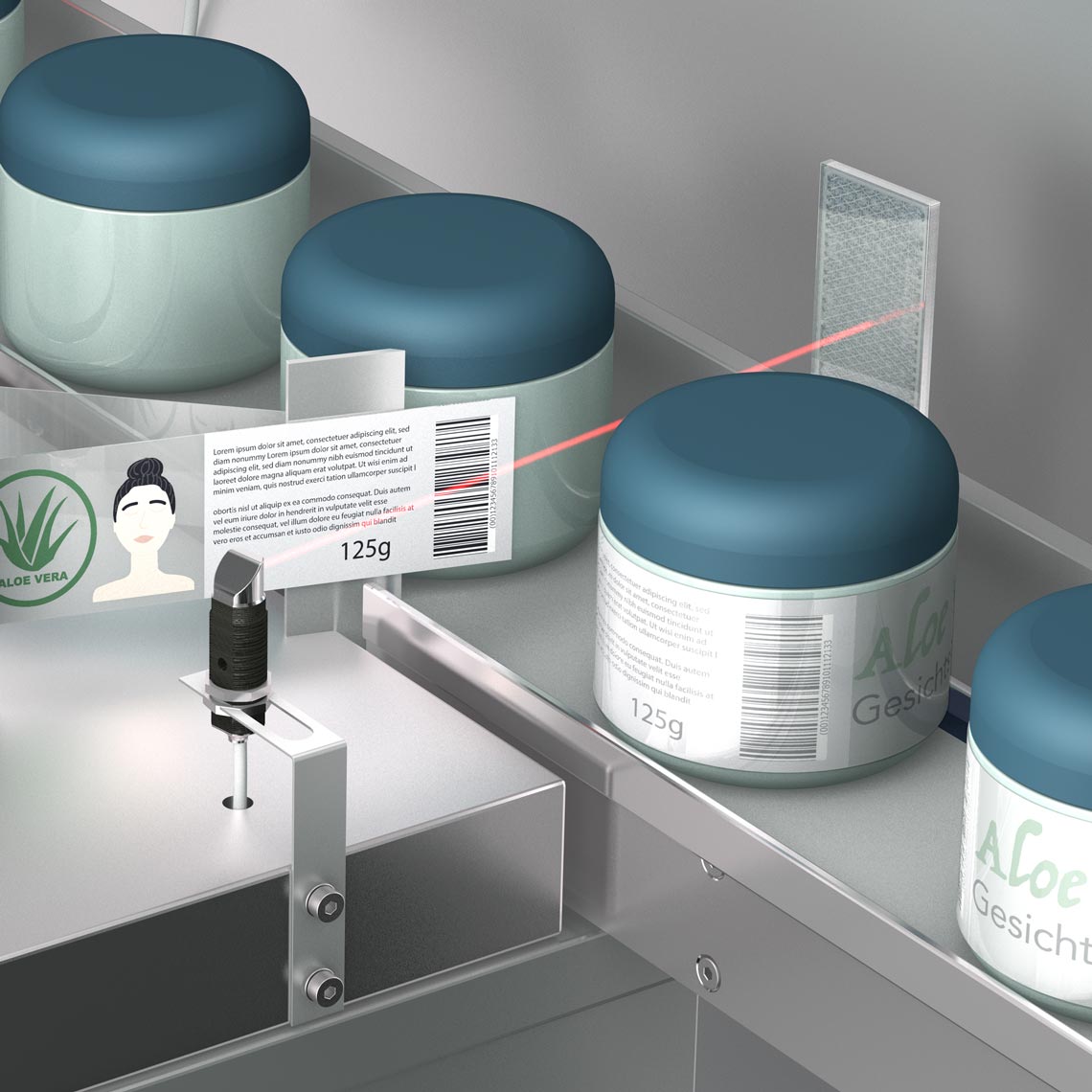

- Position check for label fit

- Traceability of products

- Track and trace 1D code

- Checking cover color

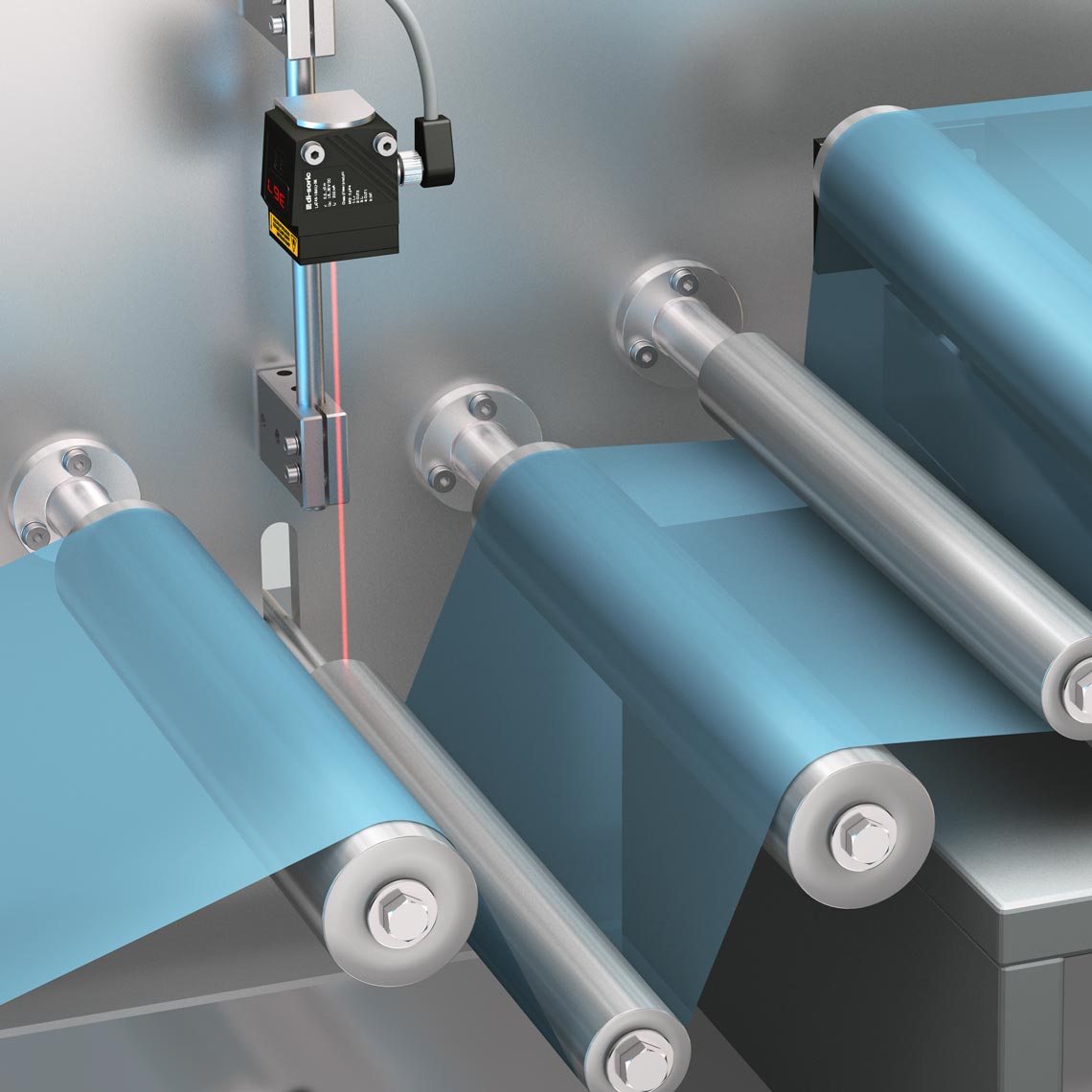

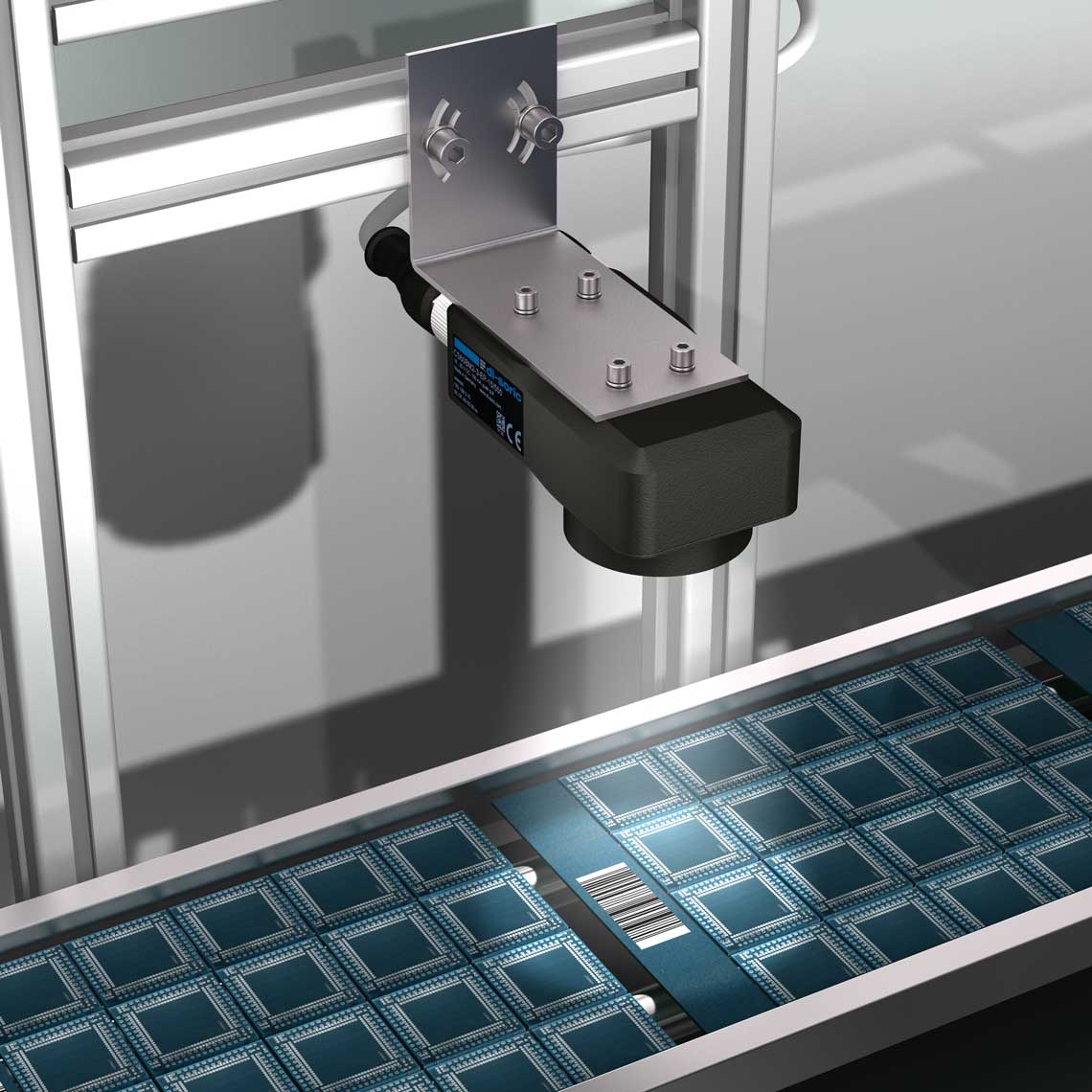

Creating labels

For precision and maximum productivity

The large number of applications and label types requires specific manufacturing methods. In order to optimally equip the various process steps and machine types, di-soric provides a range of sensors for printing, coating and laminating as well as for punching labels.

Through simple adjustment, our sensors make it easy to achieve fast, process-reliable and flexible production of varying products and batch sizes.

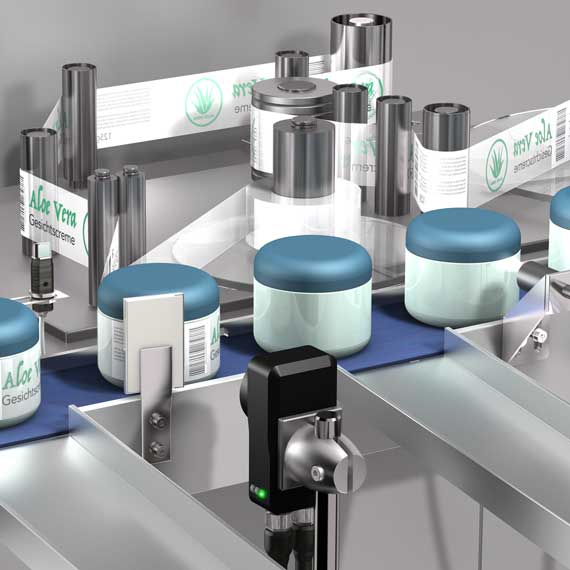

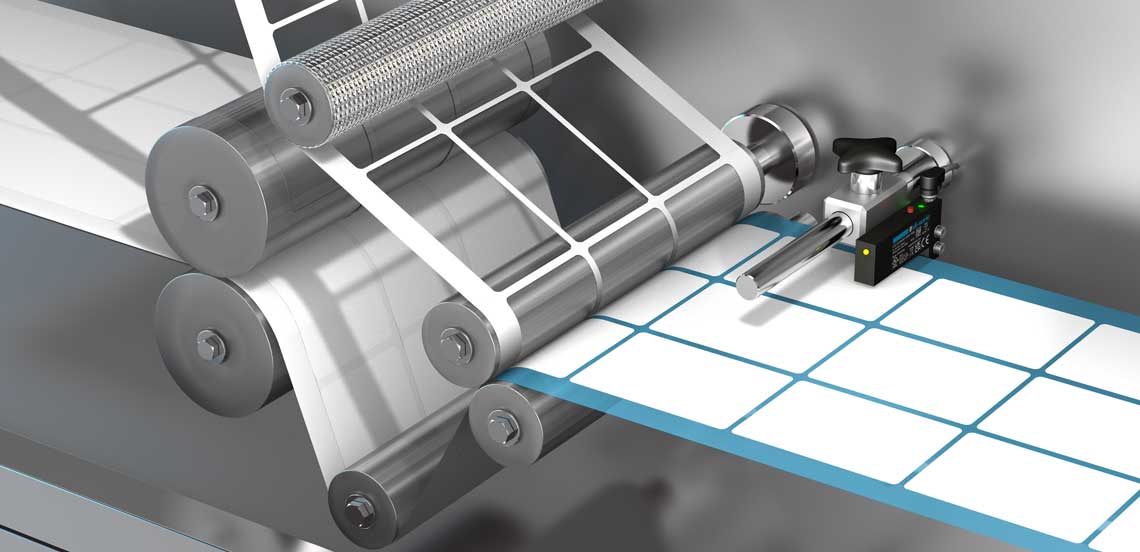

Dispensing a wide variety of labels

with speed, precision and flexibility

The number of labels processed on the market is steadily increasing. The spectrum ranges from transparent labels for the non-label look to printed and partially metallic labels and even thick booklets with integrated instruction leaflet.

di-soric label sensors are equipped with auto-teach. The ideal switching point can be determined with the press of a button while the label tape is moving through the label sensor. This way, the auto-teach feature allows for extremely fast label changes while the process is running. In addition to button operation, remote teach variants for optical, capacitive and ultrasonic label sensors are also available.

Supporting sensors

for dispensing labels fast and with precision

Inductive sensors

are always used when metallic objects are to be detected reliably.Optical sensors

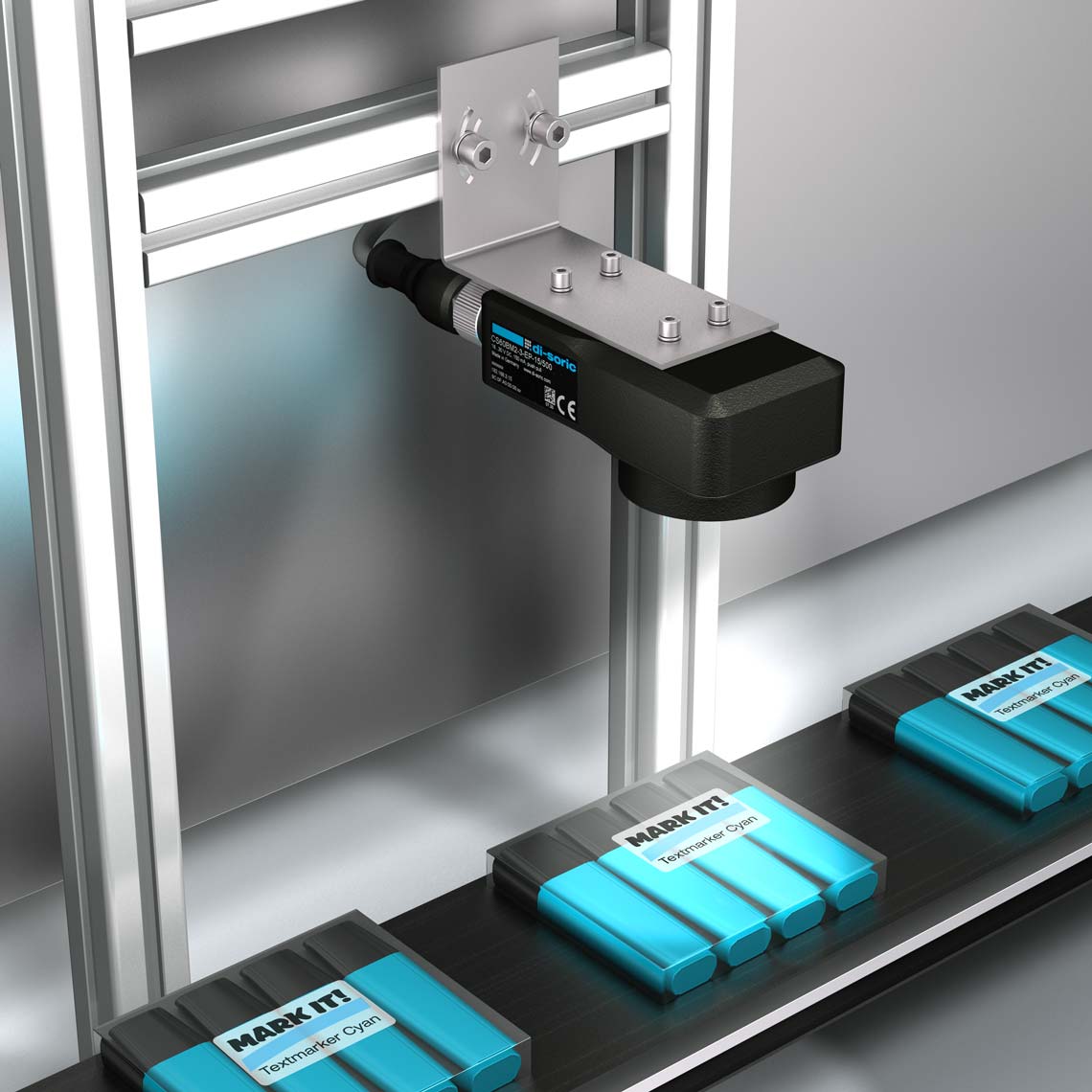

stand out for their high switching frequency, short activation time and high resolution—simply put, they are fast and efficient.Checking labeling

Error-free, fast quality control and backtracking of labeling

The ID and vision products that we offer ensure that 1D and 2D codes as well as plain text can be read and verified reliably.