Part

Feeding

As an upstream process for assembly, machining and packaging processes, reliable feed of parts is essential. di-soric offers various solutions for the correct storage, feed and provision of the components—each of them adequate for the individual requirement of the application.

Limited installation space, a wide variety of materials and sizes, high speeds and the increasing use of robots pose particular challenges to the control and monitoring of part feeding. Compact designs and a high availability of the sensors, vision sensors and signal lighting are required.

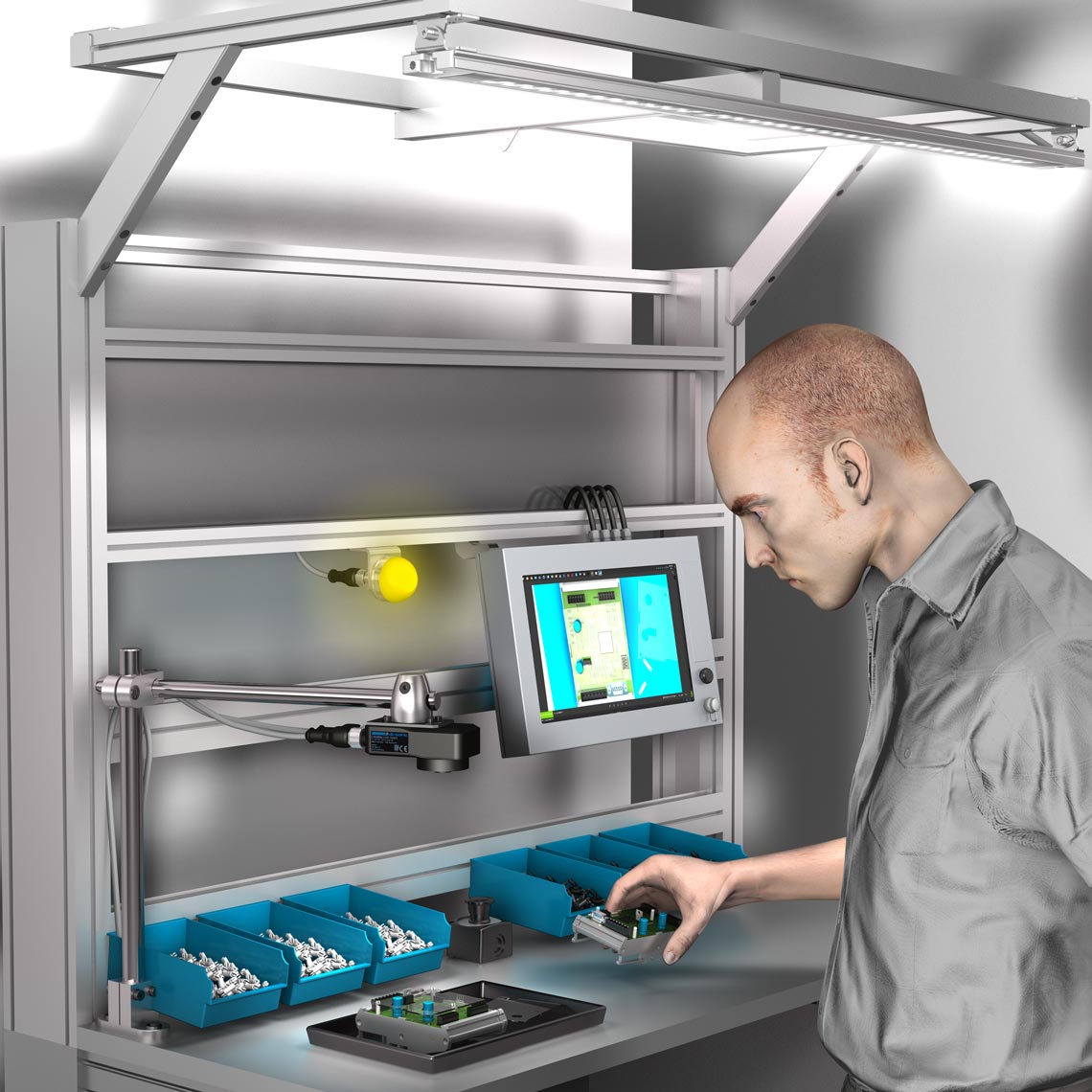

Optimized adjustment, maintenance and monitoring

In addition to the suitable product solution, easy integration into the system is also important for ensuring a reliable process. For this purpose, our products are equipped with industrial interfaces such as Ethernet TCP/IP, PROFINET and IO-Link, thereby supporting optimized adjustment, maintenance and monitoring of the entire system.

Flawless and safe operation

Also you can efficiently prevent machine downtimes caused by empty storage, material accumulation and incorrect orientation of components with di-soric sensors and solutions. It does not matter whether the application uses linear part feeding, step feeders, circular or vibratory feeders, feeding in tubes or manual feed—our solutions ensure flawless and safe operation of your system.

Sensors and image processing solutions for reliable part feeding:

Sensor and image processing solutions for reliable part feeding:

Assembly and handling technology

Packaging technology

Robotics

Image processing

IO-Link

Download / Info

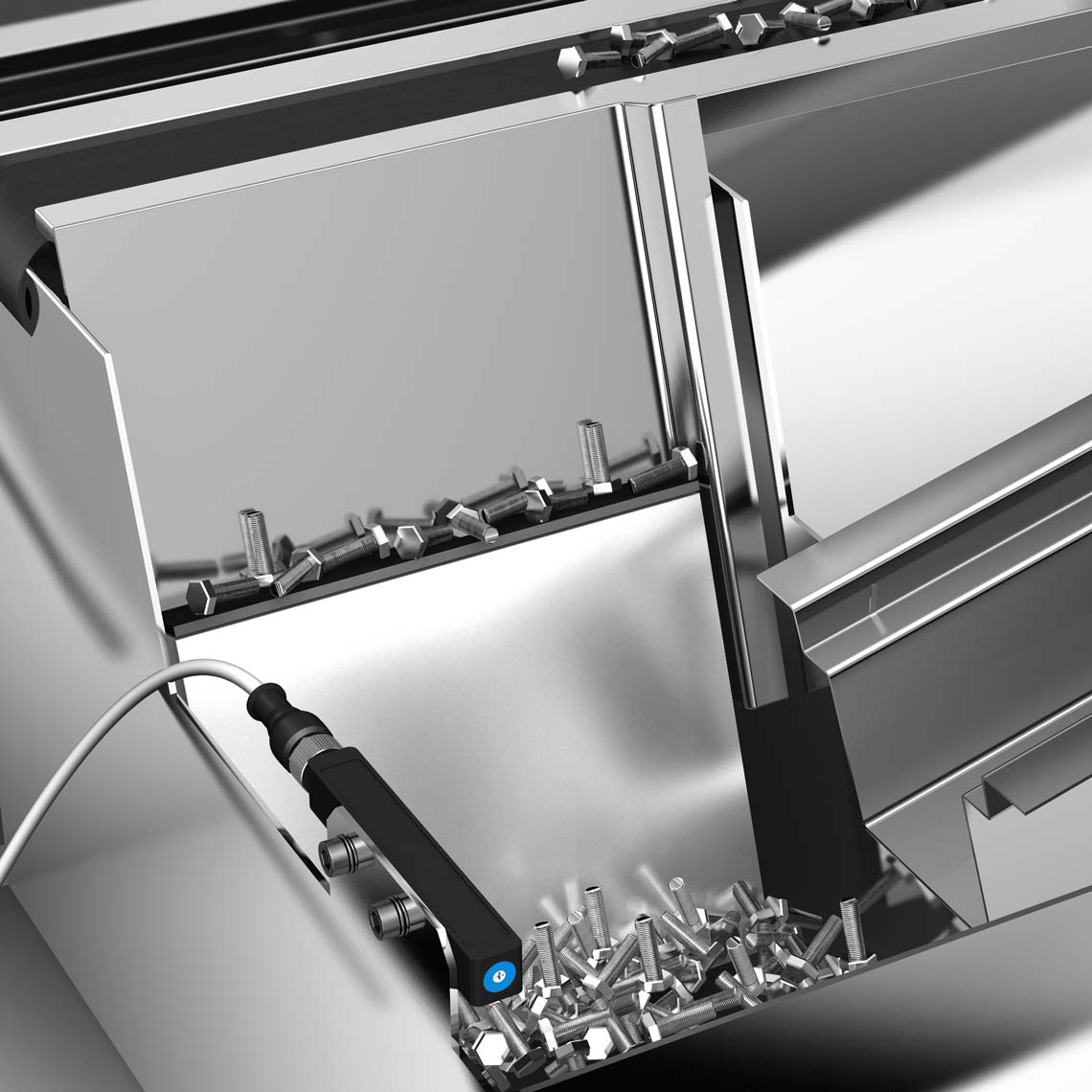

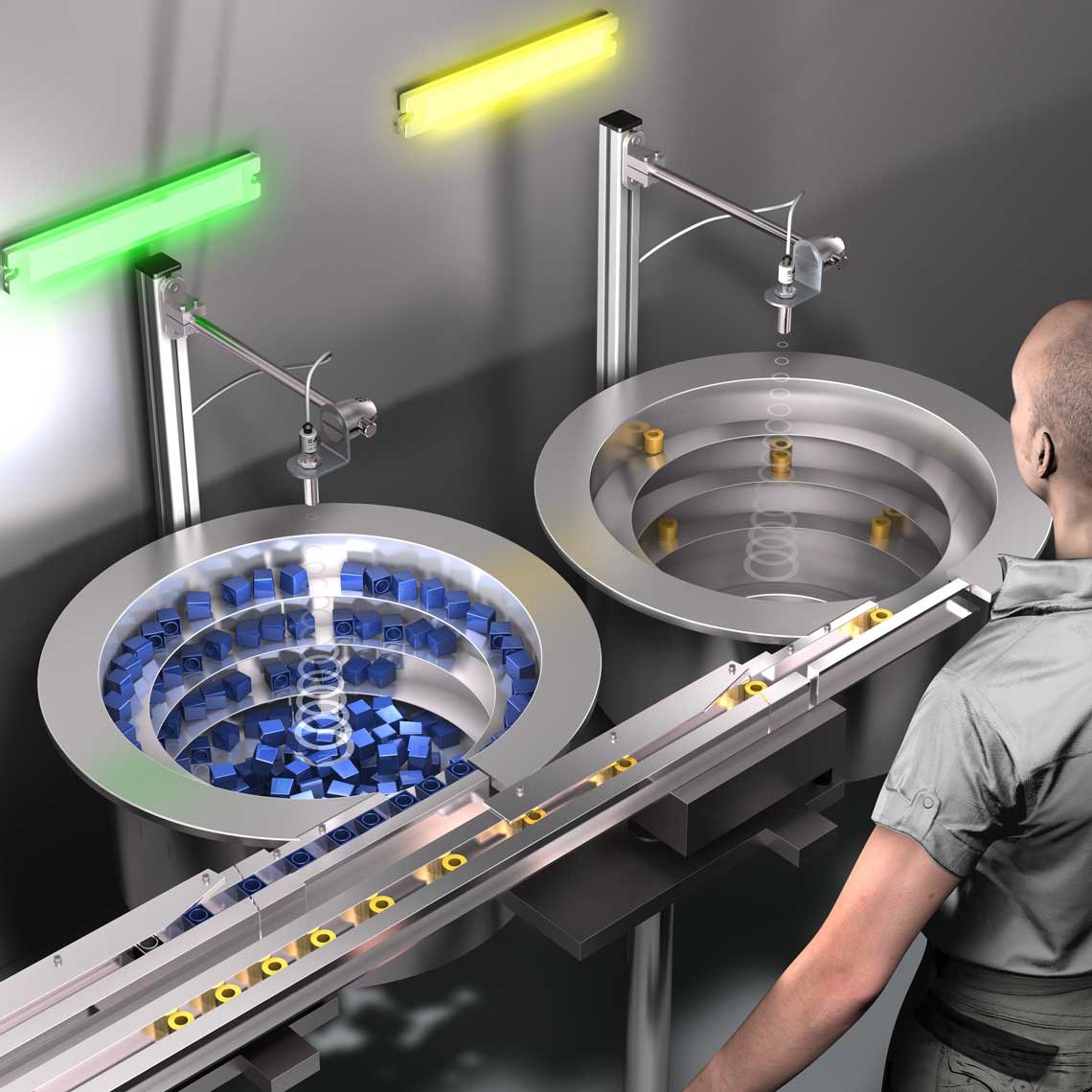

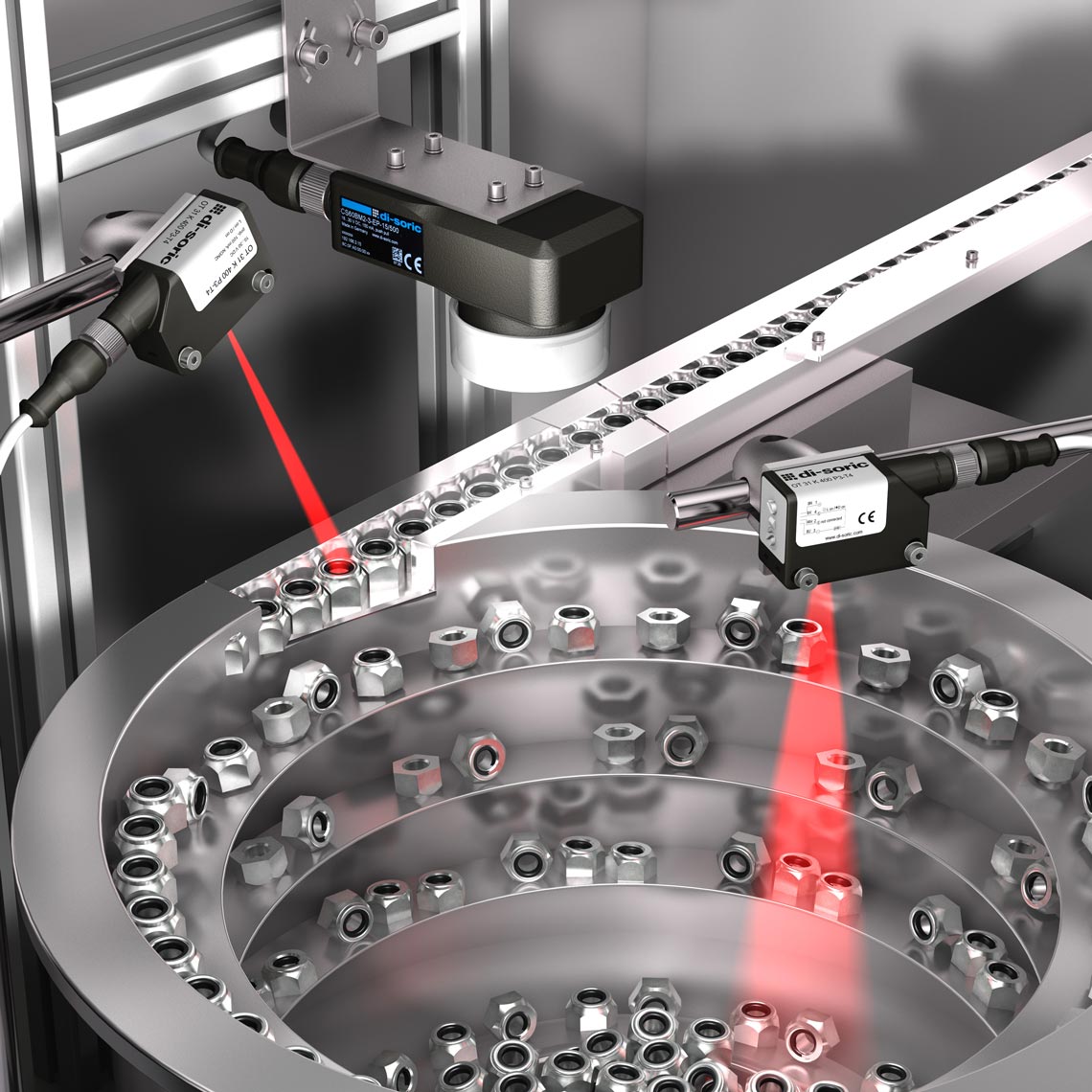

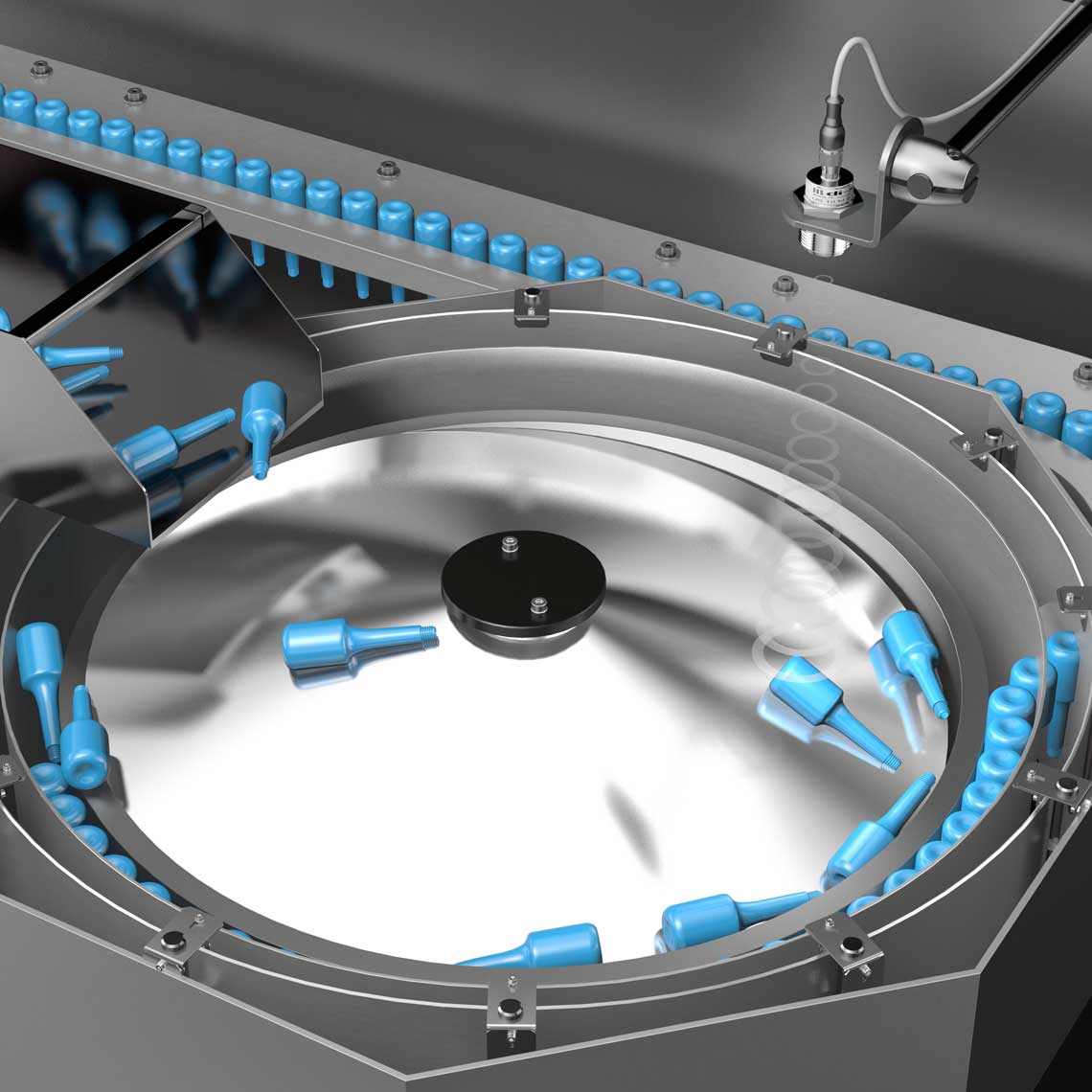

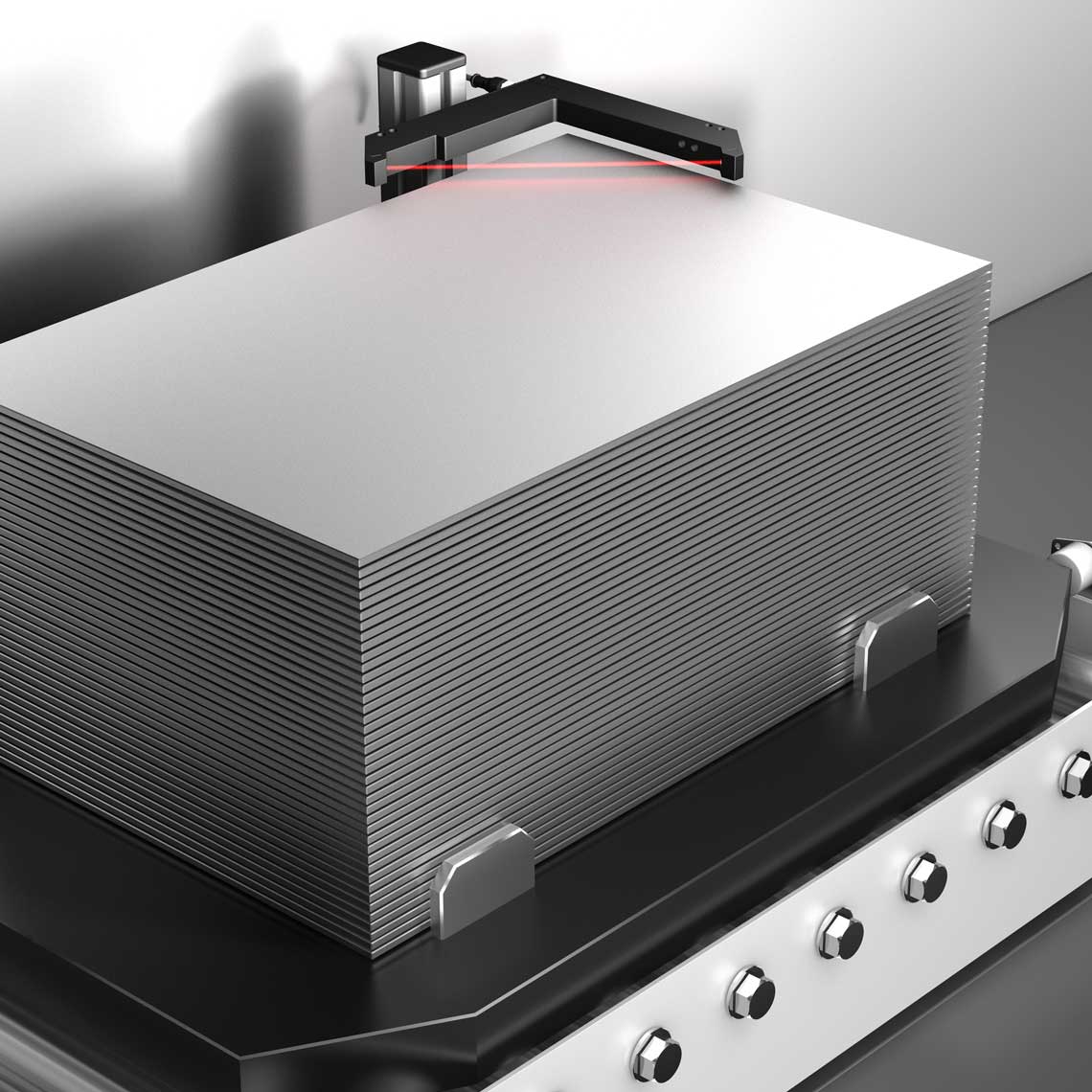

Storage

of components and material

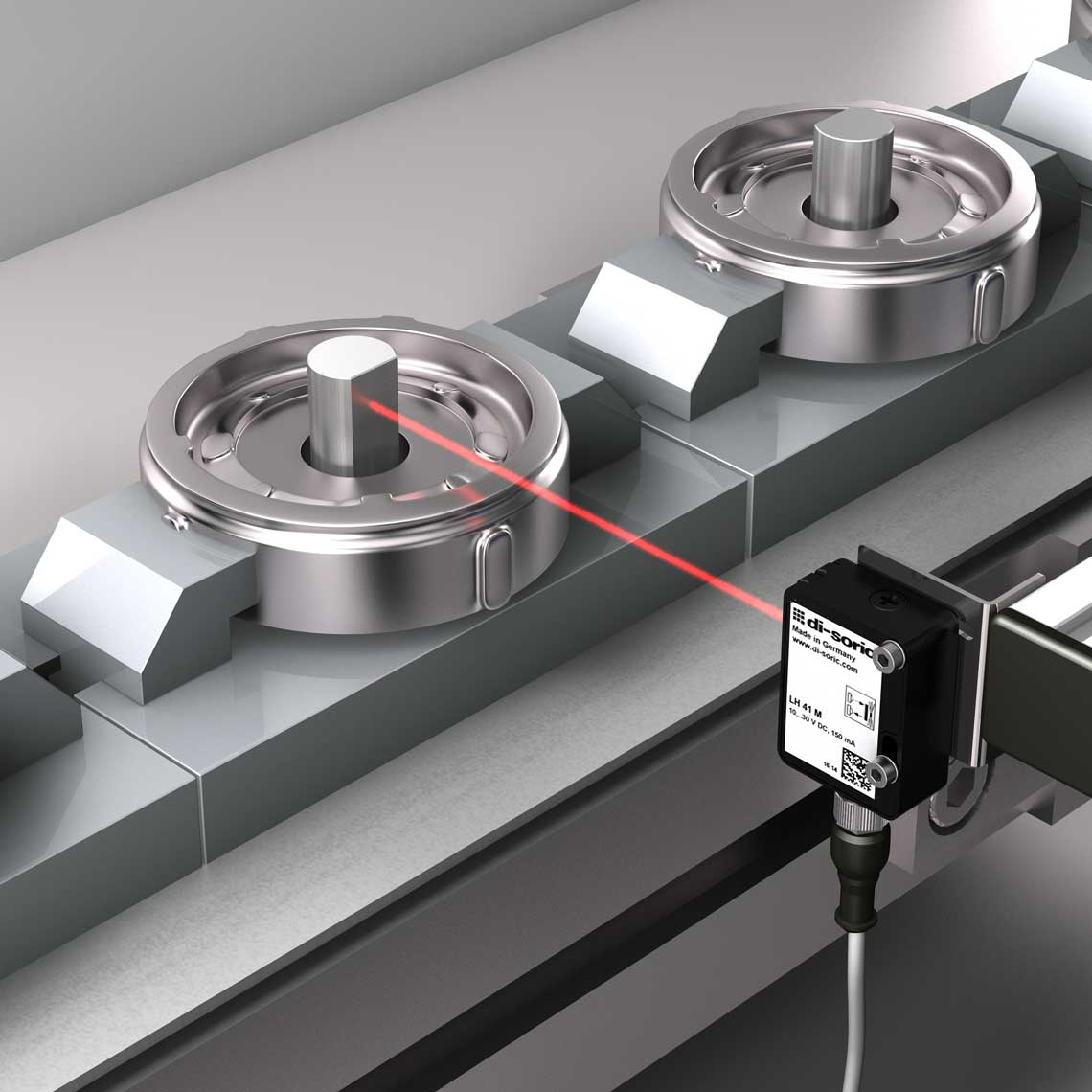

In the segment of feeding in assembly and handling technology, components must always be available in sufficient quantity in circular or step feeders for further processing. Our optical sensors and ultrasonic sensors monitor reliably—without contact or wear.

Depending on the degree of automation, it is possible to carry out automatic or manual refilling in a timely manner—and while minimizing downtimes—when the level falls below a target value.

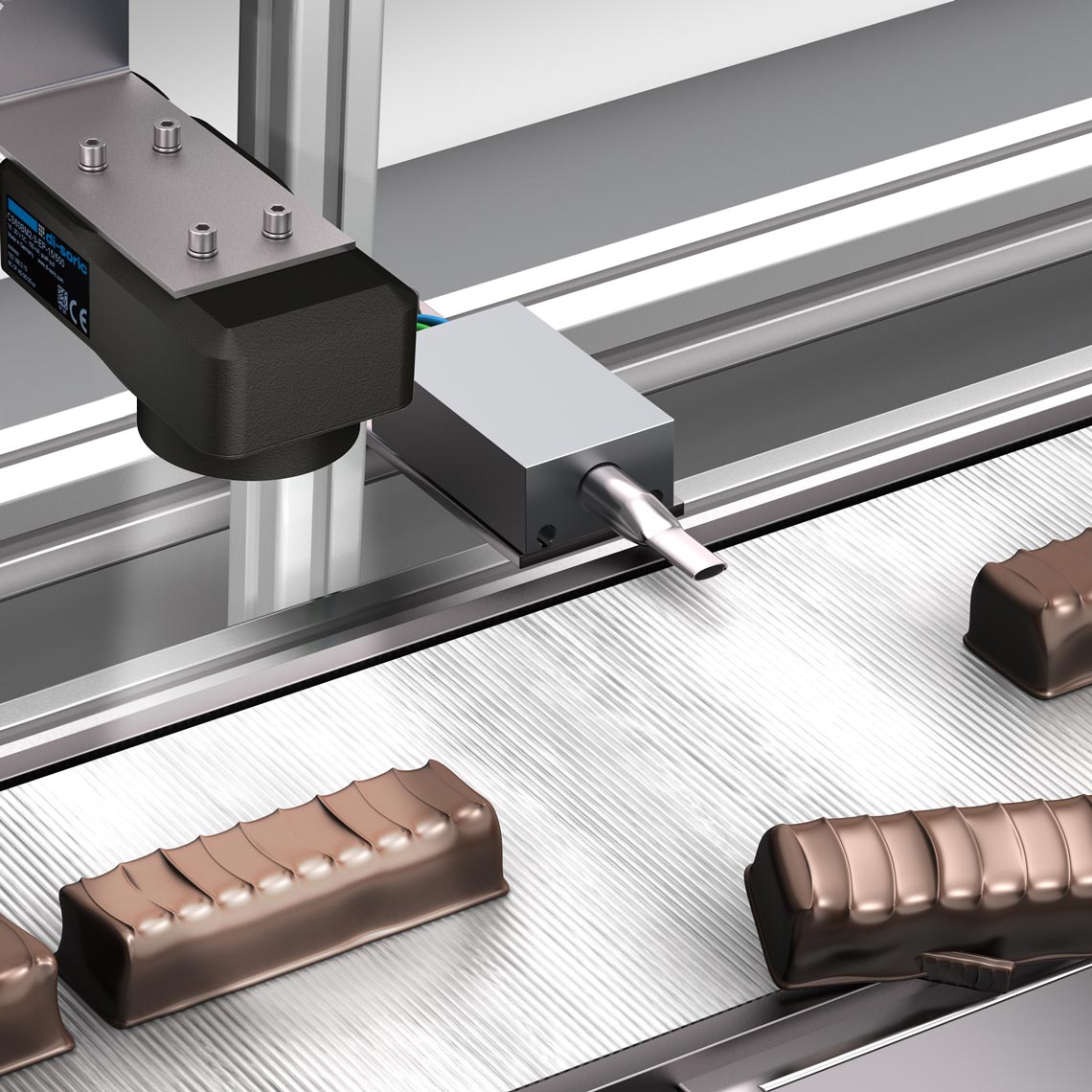

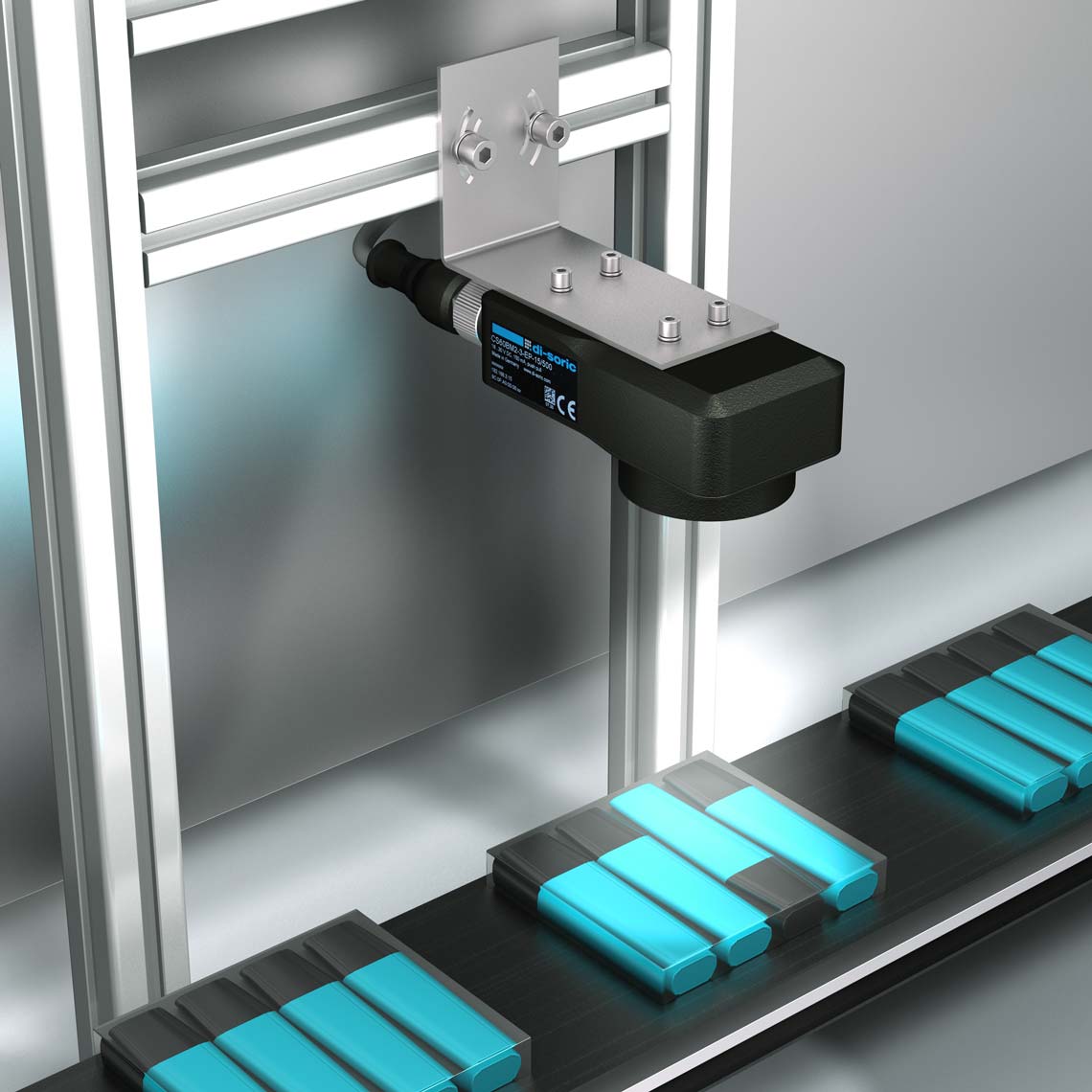

Linear

part feeding

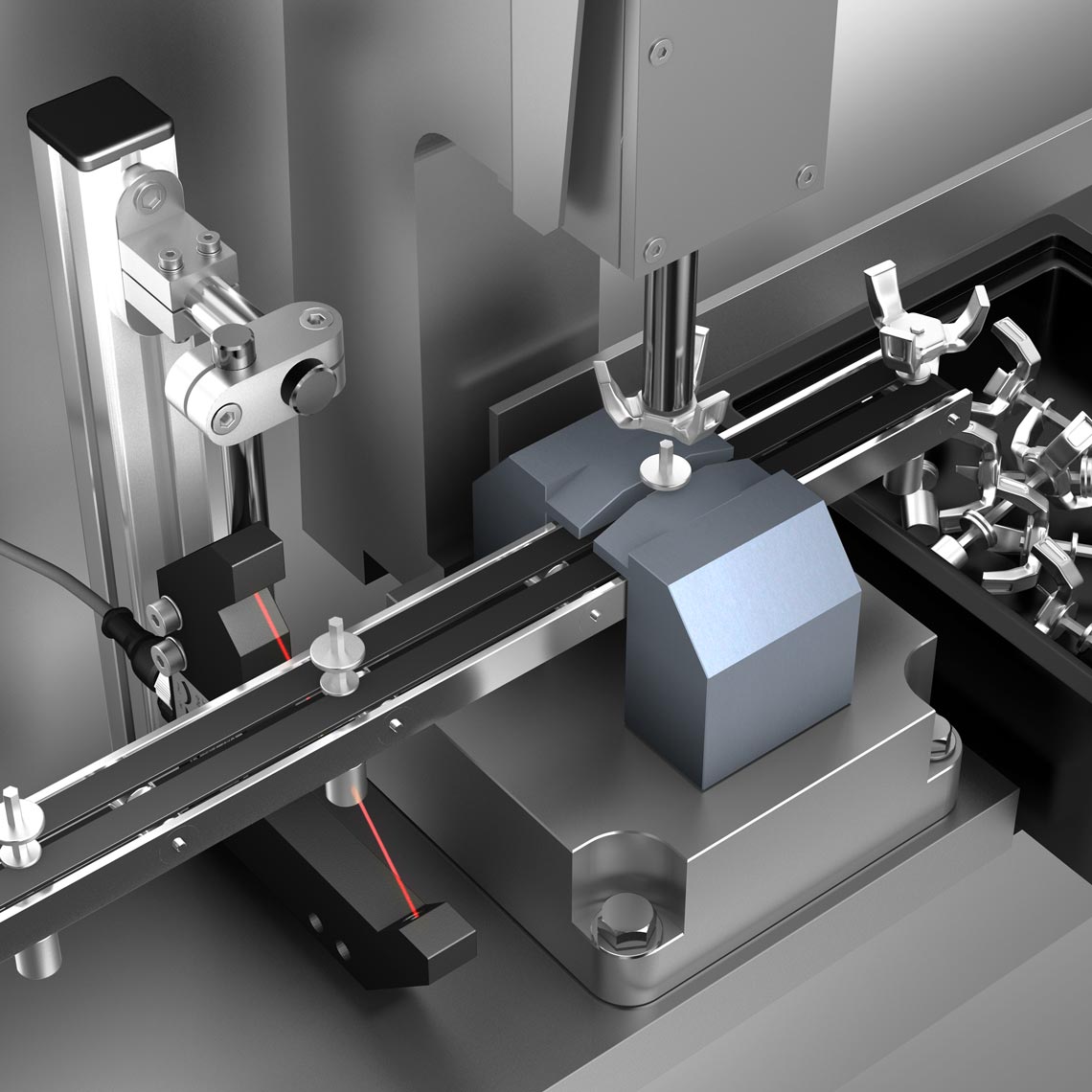

Our sensors reliably control the continuous material feed of the downstream assembly. It does not matter whether parts are being fed on rails, belts, workpiece carriers, pallet or chain feeders. Our sensors feature accumulation and feed control that ensures maximum availability and functional reliability in downstream processing steps such as pressing, assembling, forming or closing. The wide range of solutions from di-soric offers a suitable solution for every type of linear material feed.

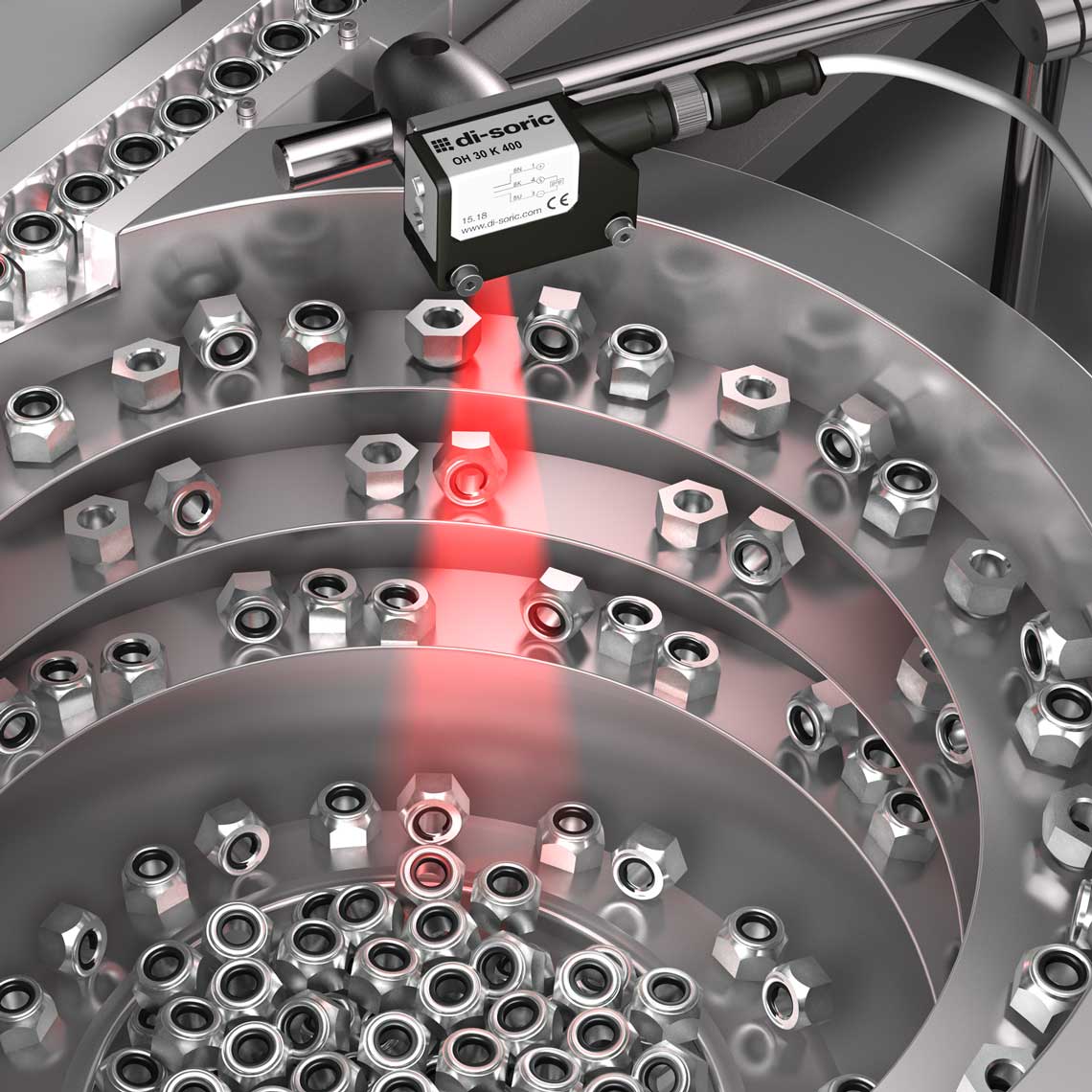

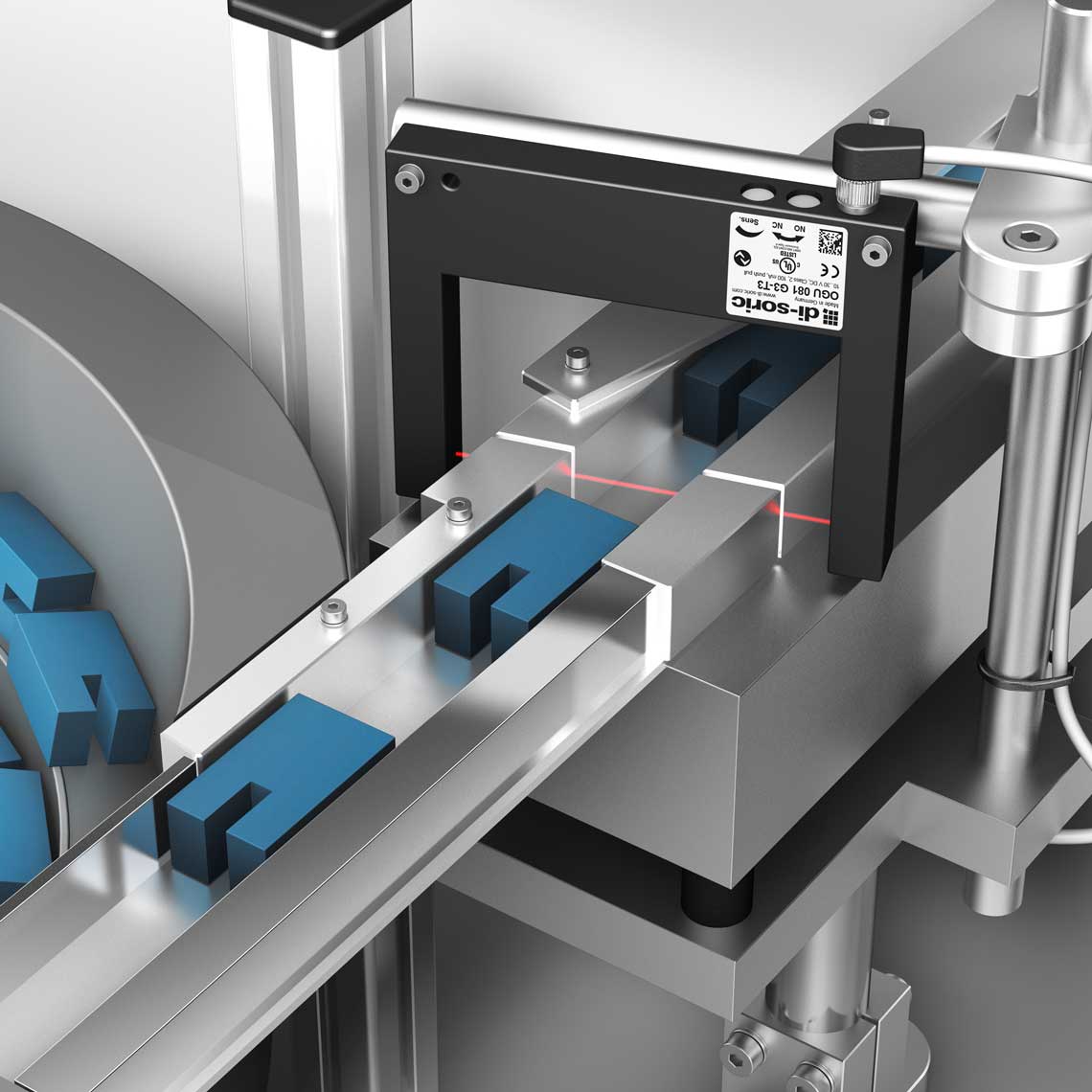

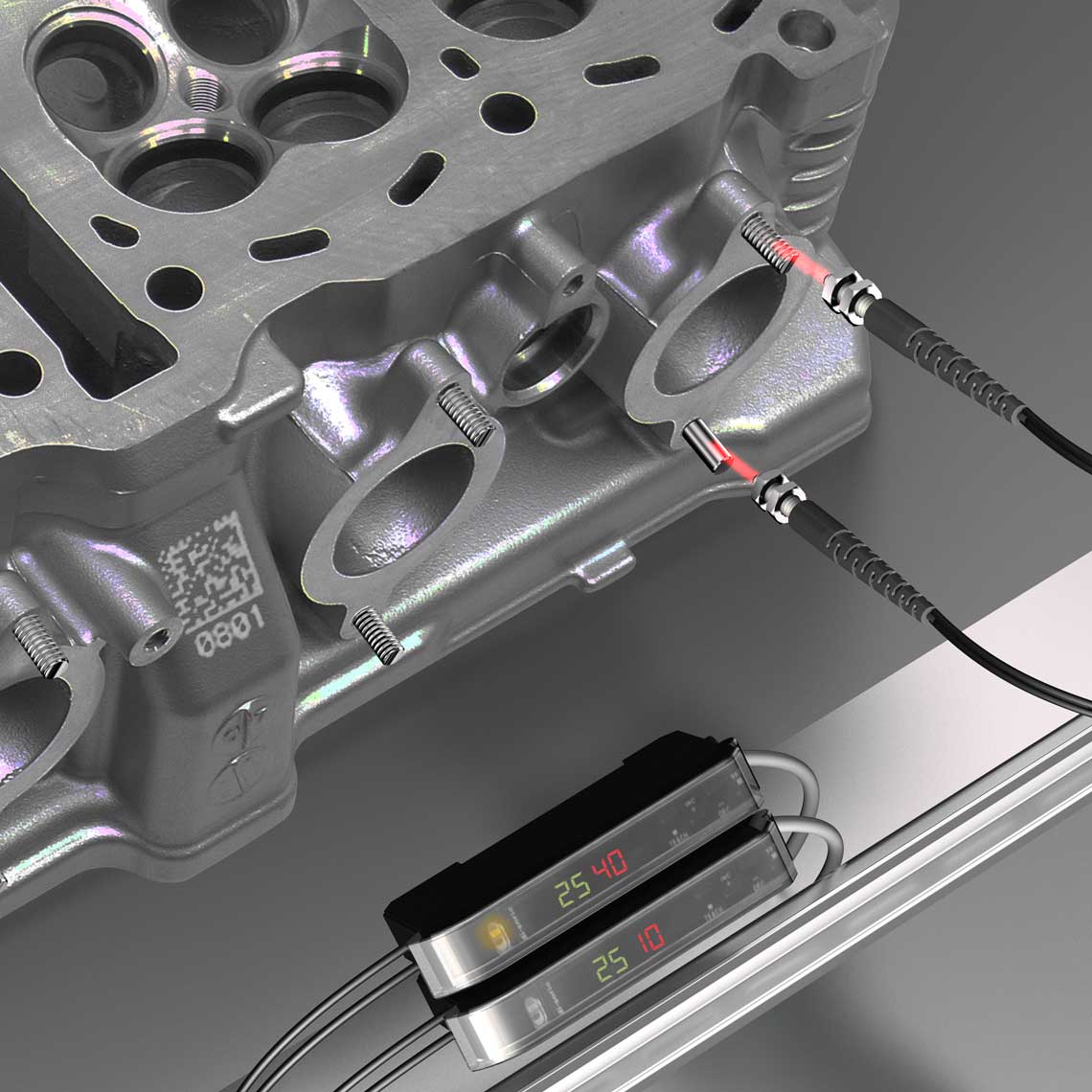

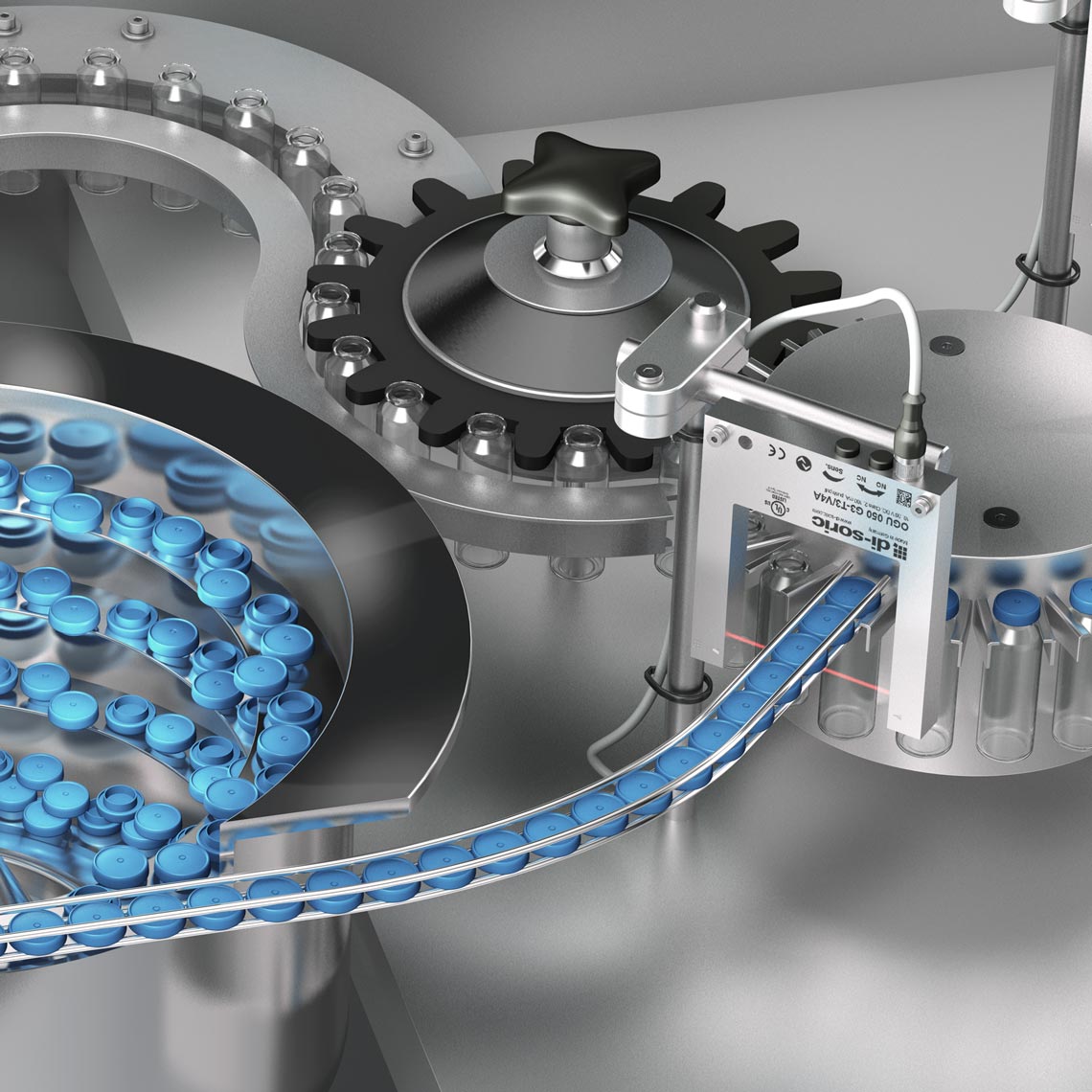

Position monitoring

of part feeding

Components must be checked for their position and completeness before they are fed to assembly machines. For this purpose, di-soric has a wide selection of product solutions that increase productivity, minimize machine downtimes and even prevent machine damage.

Our high-resolution laser sensors for the detection of the smallest features or fiber-optic sensors in constrained installation spaces are excellently suited to these tasks. If entire areas must be checked, our vision sensors are used.

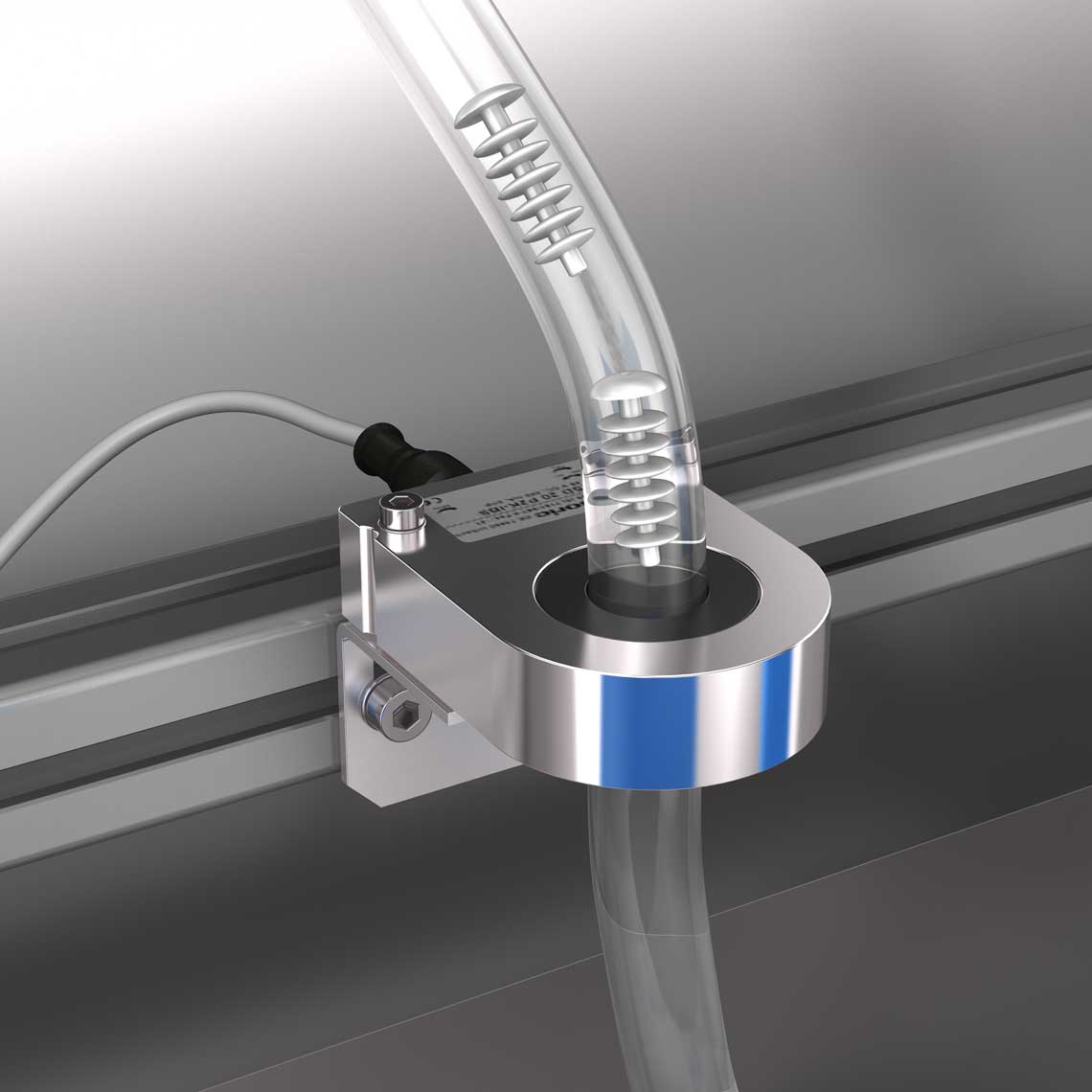

Feeding Parts

in a tube

Components such as screws, springs, washers or welding bolts are fed to the assembly process by means of tubes. For this purpose, di-soric has a wide selection of optical ring light barriers and inductive ring and tube sensors with dynamic and static detection.

For feeding both metal and plastic objects, our portfolio provides the suitable ring sensor in various sizes. Our tube sensors are suitable for flexible attachment to various tube diameters.

Tubular bag machine

and sealing machine

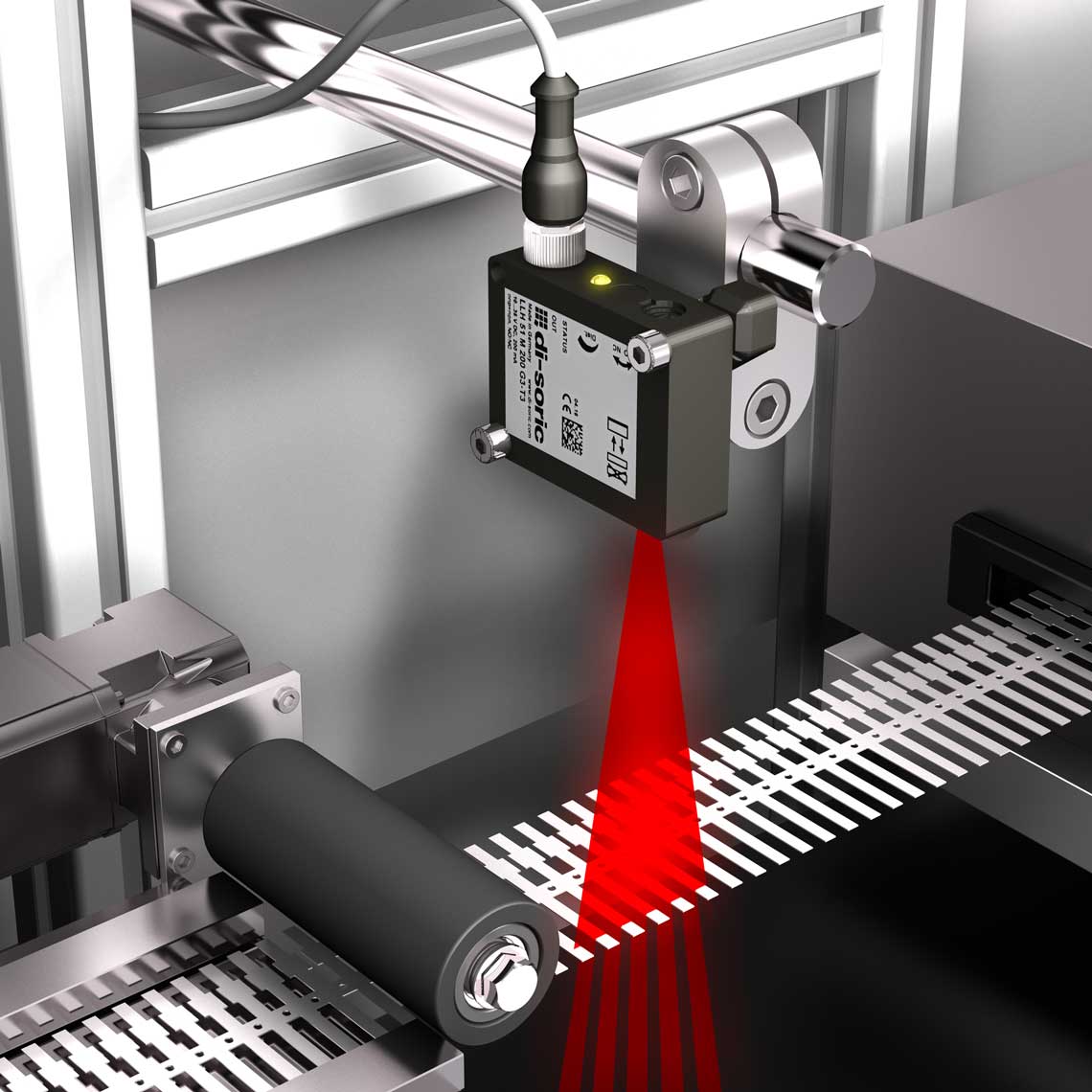

In packaging processes, frequent product changes, varying objects and designs call for safe object detection. In addition, large production quantities impose the highest demands on the inspection rate of the sensors in packaging technology. For this purpose, di-soric provides sensors that can be adjusted quickly and easily and solutions for object detection at very high speeds.

If tasks become too complex to be handled by sensor technology alone, our vision sensors with their easily configurable tools are often the suitable solution.

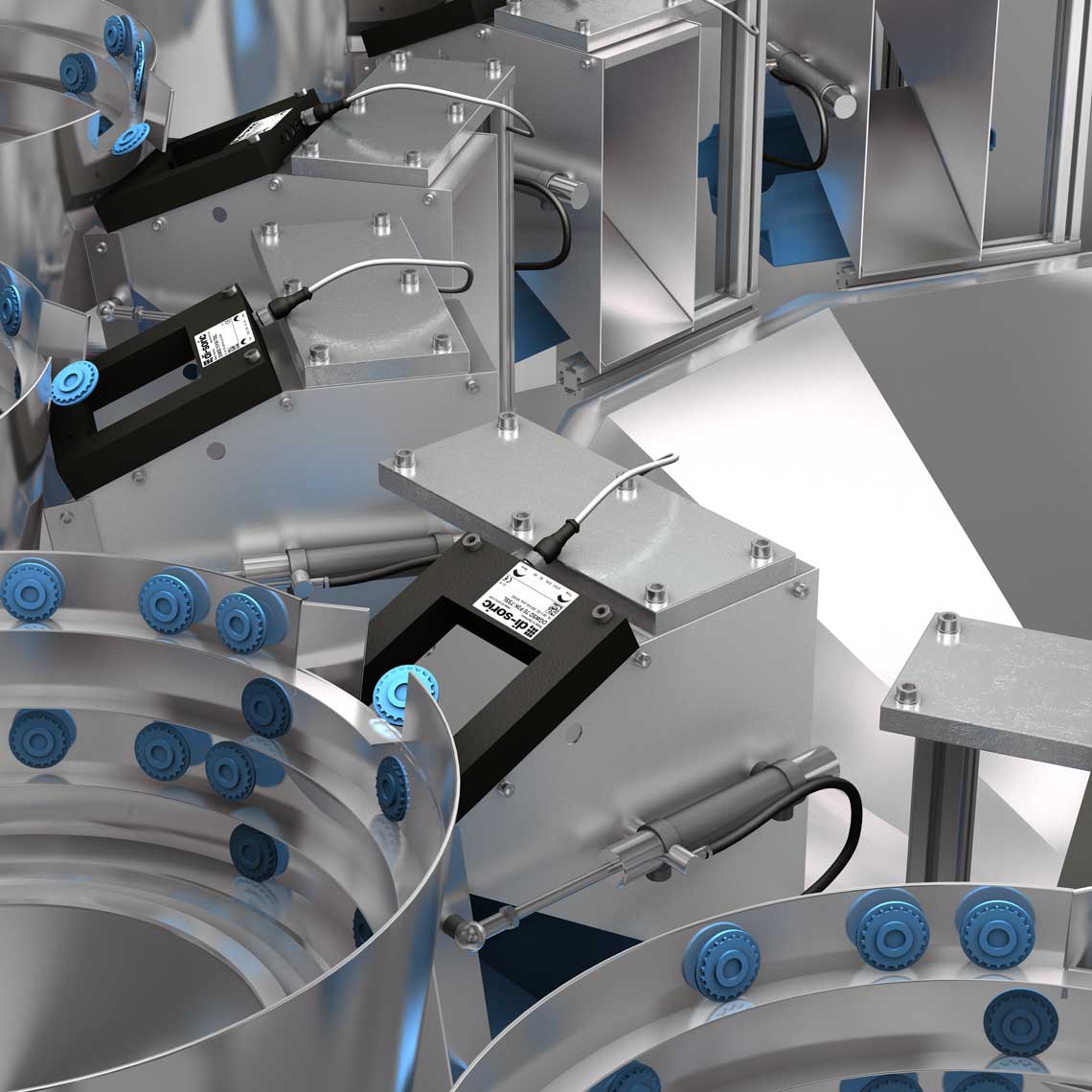

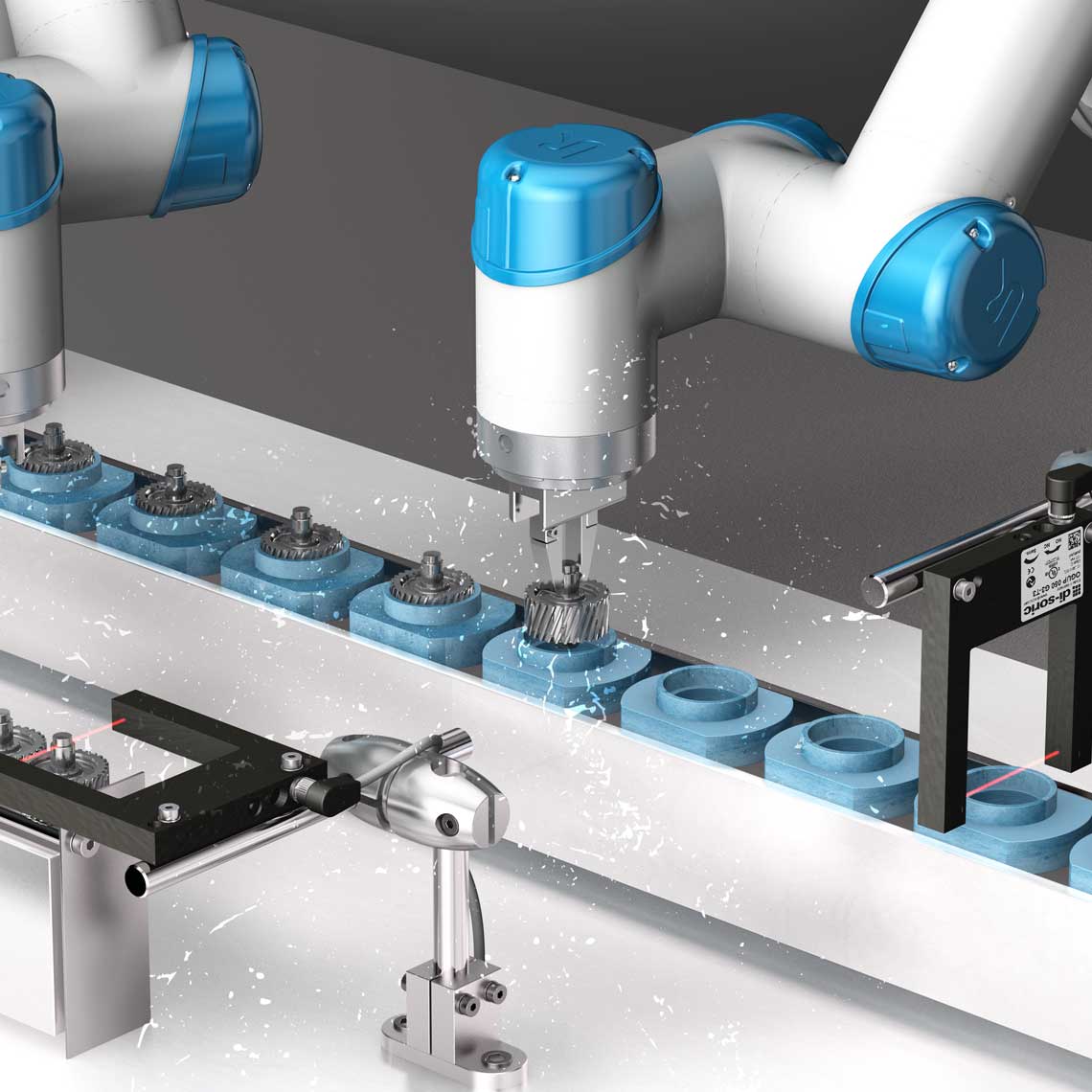

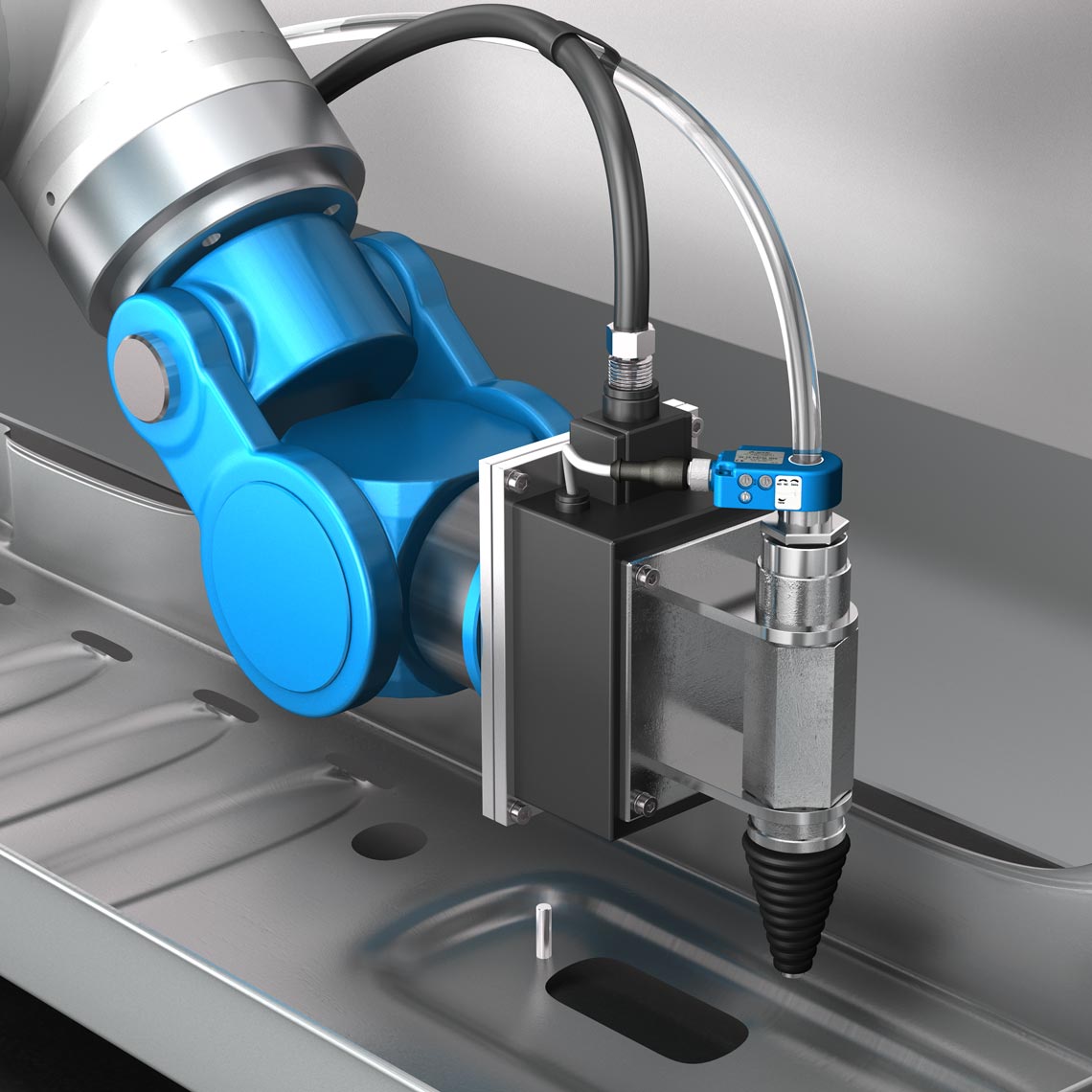

Sensors and safety

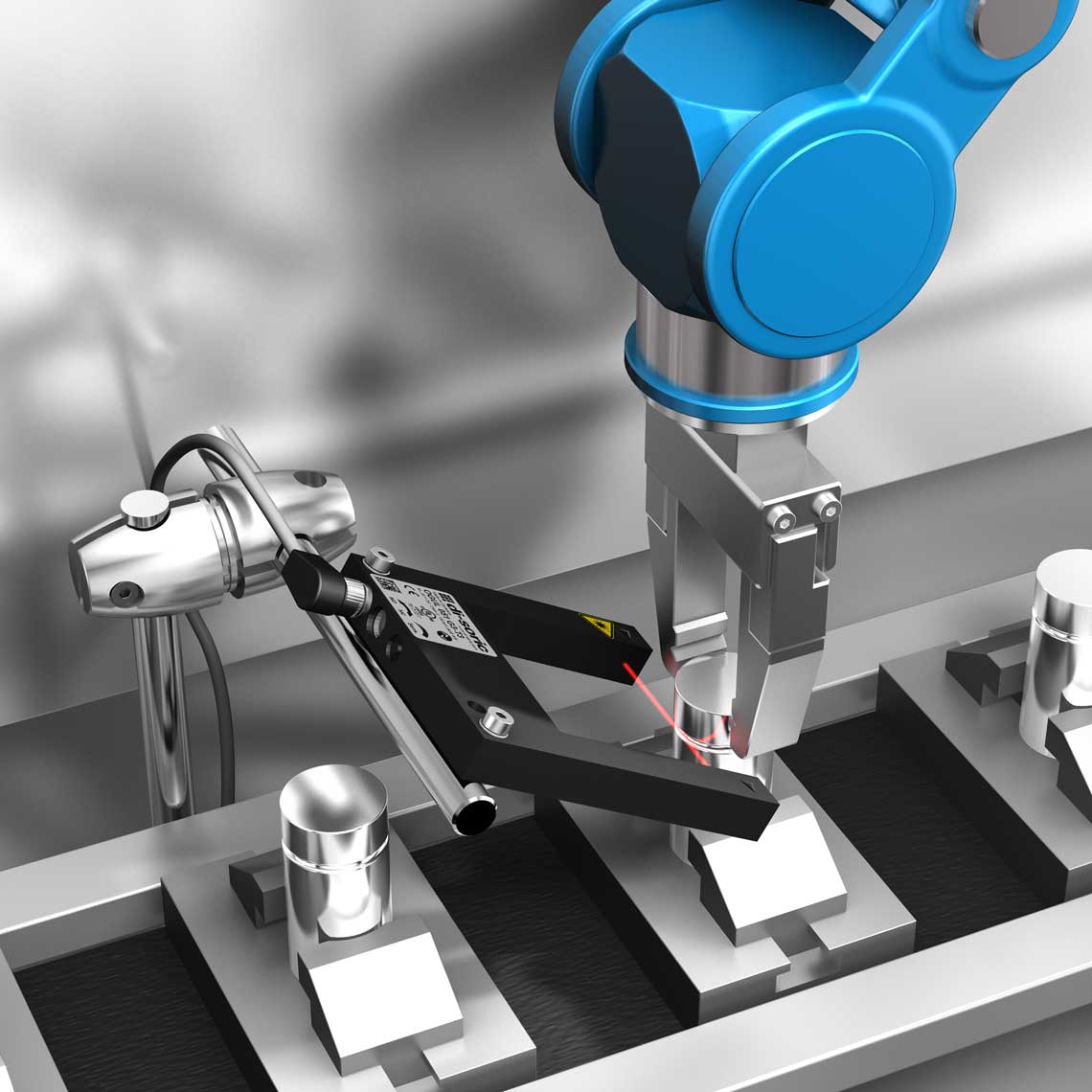

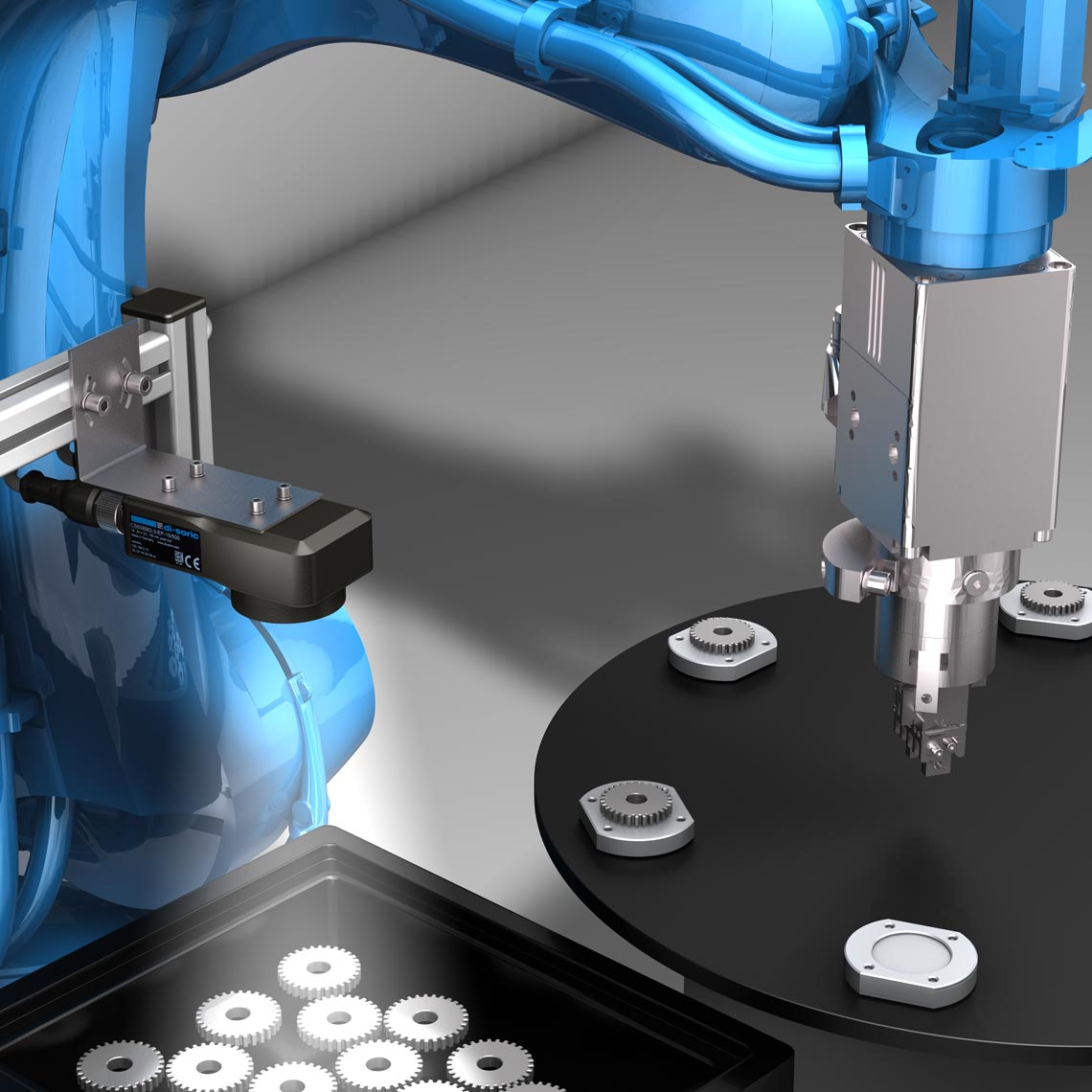

in robot-assisted processes

In robot cells, sensors can be used to handle an extremely wide variety of challenges. Our sensors and vision sensors function as the sensory organs of the robot. They ensure material detection and monitor the flow of parts reliably.

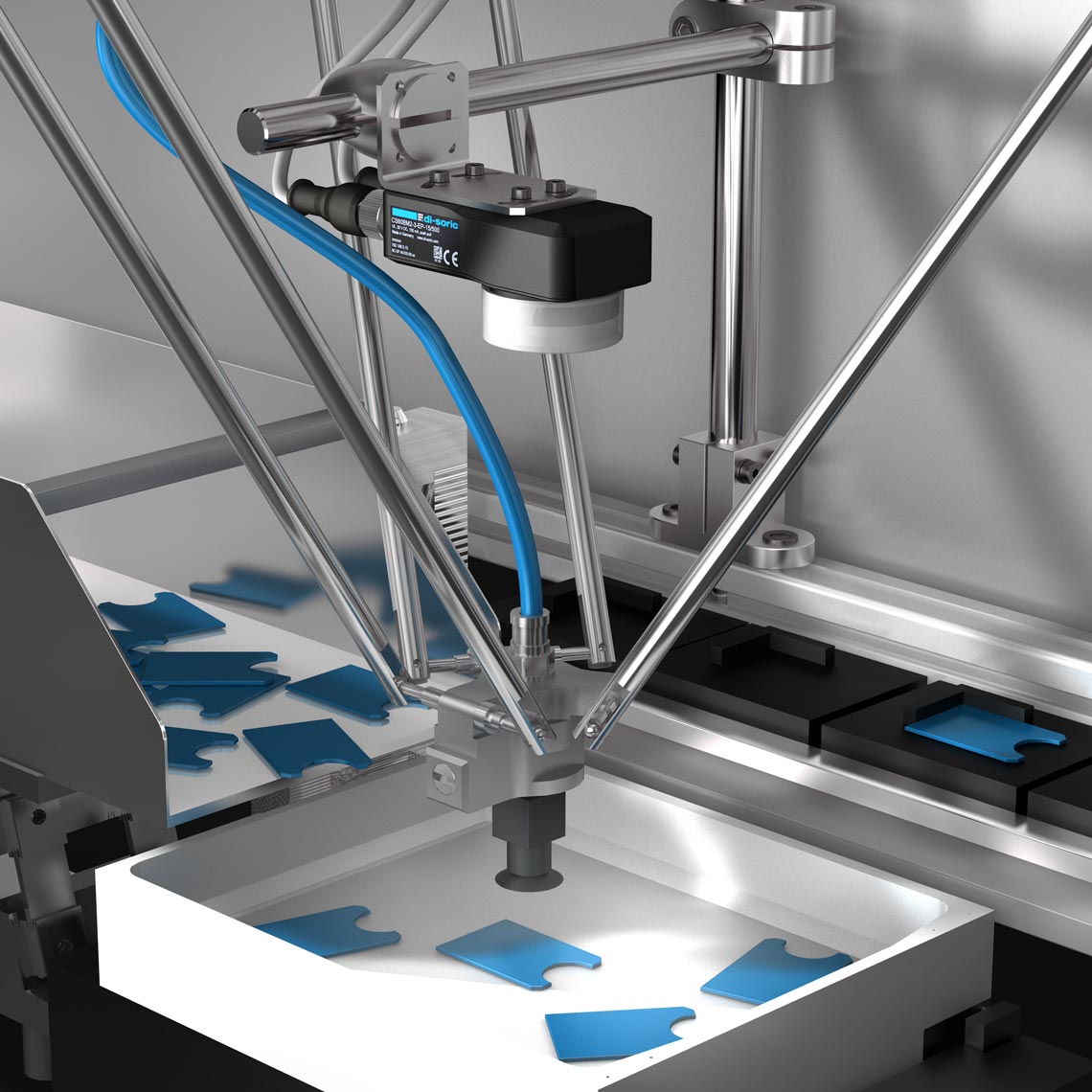

Vision Sensors

for more demanding applications

Our vision sensors are intuitive to use and can be put into operation in a few minutes without training. Deployable out-of-the-box, they feature comprehensive, easily configurable software tools as well as standardized interfaces for communication with peripherals.

When tasks become too complex for sensors alone, our vision sensors are often the right solution.