nVision-i

The image processing software of our vision sensors CS-60

and ID readers ID-600

Save time

Not only because of an interface that is clear, intuitive and easy to use, but also because of the high-performance tools that are consistently optimized for the highest quality with maximum performance.

Industry-leading algorithms for high read rates

With the comprehensive, high-performance tools and integrated image optimizations, optimum performance is achieved with smooth commissioning and changing requirements. If required, the tools can be extended by a software upgrade or customized individually.

The visualization of the pipeline and linking of individual tasks in the Logic tool make the greatest degree of flexibility and high speed in the realization of the application possible.

nVision-i

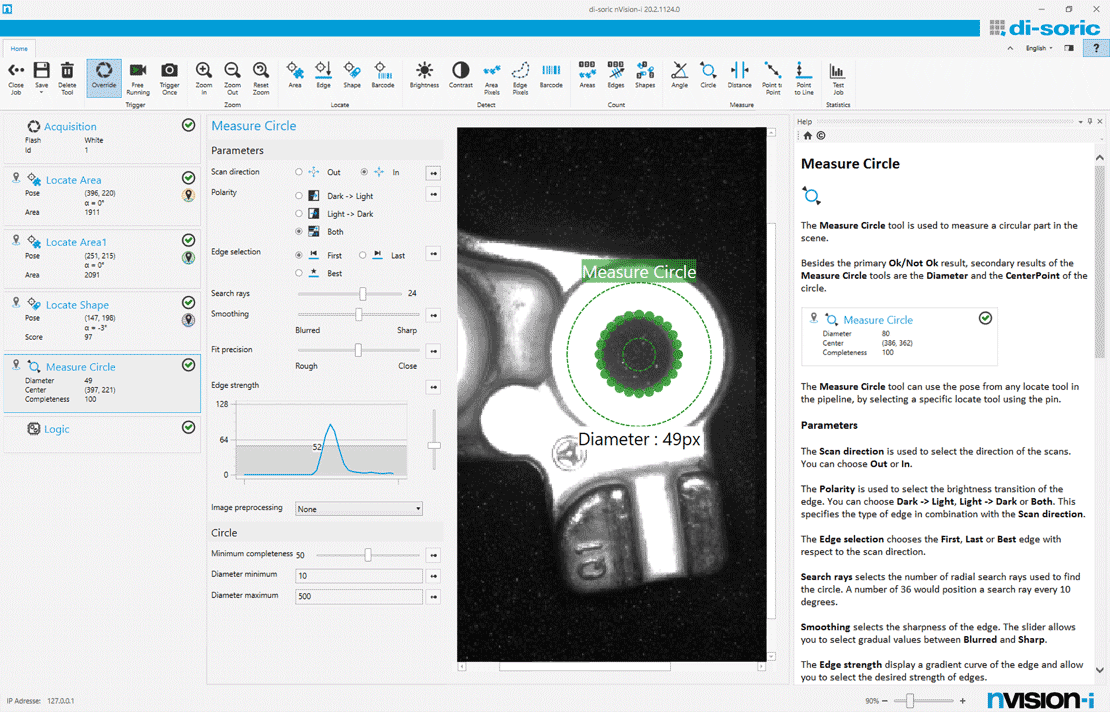

The interface

Pipeline & status checks

- Verification tools can be inserted on the left and moved via drag & drop

- Measured values and test results/status are also shown on the left side

Navigation bar & verification tools

- Intuitive and user-friendly navigation menu

- Contextual help can be displayed as needed

- Menu guidance available in 7 languages (German, English, French, Italian, Spanish, Chinese and Korean)

Configuration

- Parameters for search criteria can be adjusted simply and directly

- Limit values for the evaluation criteria can be entered easily

Display & Drawing tools

- Image viewing for checking and analysis during operation

- Context-sensitive description of the tools on the right side to ensure optimal tool use with their complete functionality

nVision-i

Image processing tools

Fast and simple

Via comprehensive image processing tools, both the verification of the quality and completeness of parts is possible as well as their localization and the transmission of determined positions by way of various communication interfaces.

Demanding tasks, such as quality inspections of highly reflective objects and applications in changing ambient lighting situations or at high speeds are reliably performed.

Tools for Vision Sensors CS-60

Detect the presence/absence of a feature based on pixel values and contrast

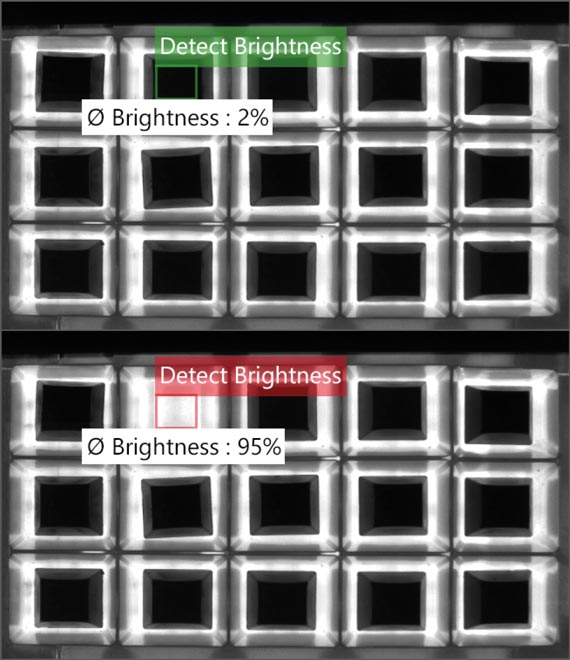

Detect Brightness

Detects the average brightness as a function of the threshold range within a defined area in the image

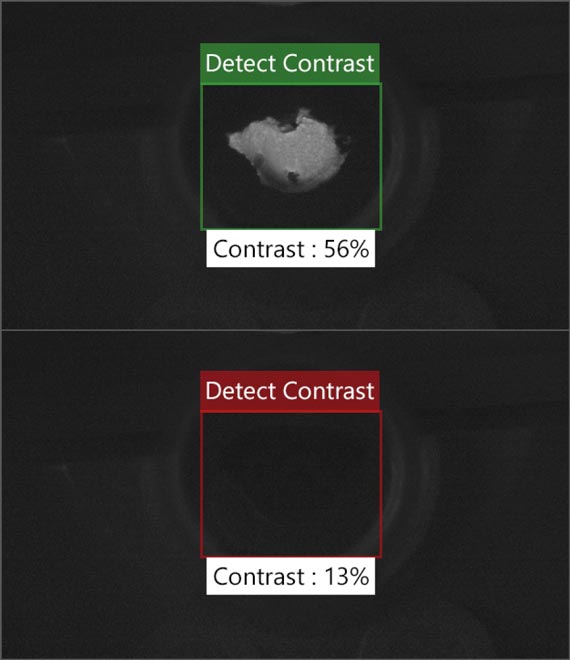

Detect Contrast

Detects the contrast as a function of the threshold range within a defined area in the image

Detect Area Pixels

Detects the number of pixels as a function of the threshold range within a defined area in the image

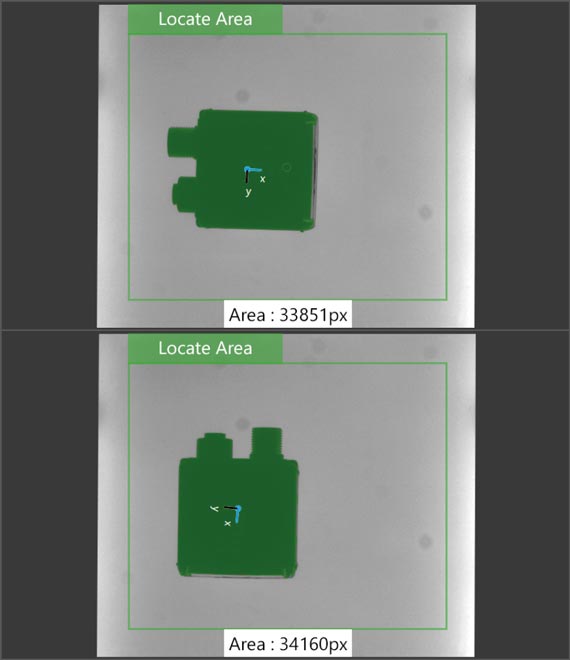

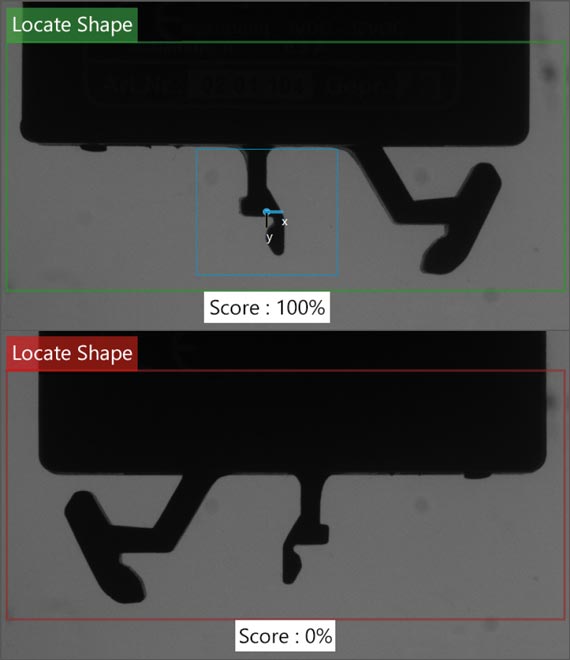

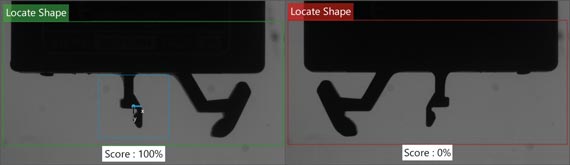

Locate areas, edges and shapes

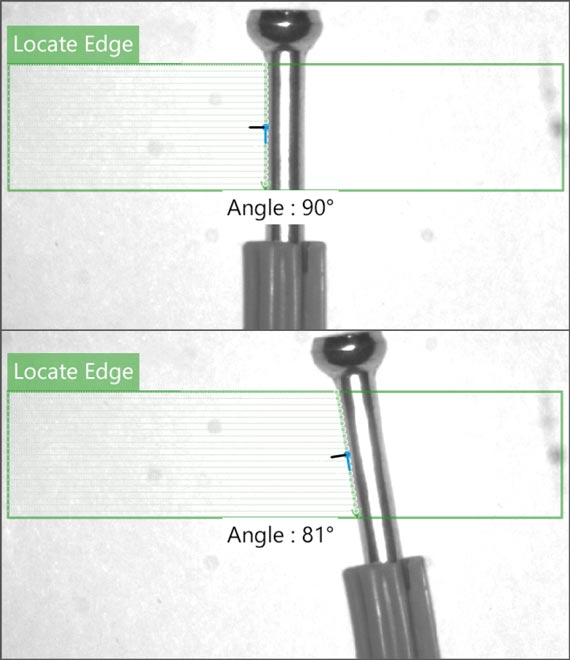

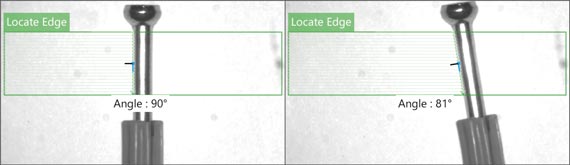

Locate Edge

Finds an edge within the defined search field and serves as a guide for subsequent tools

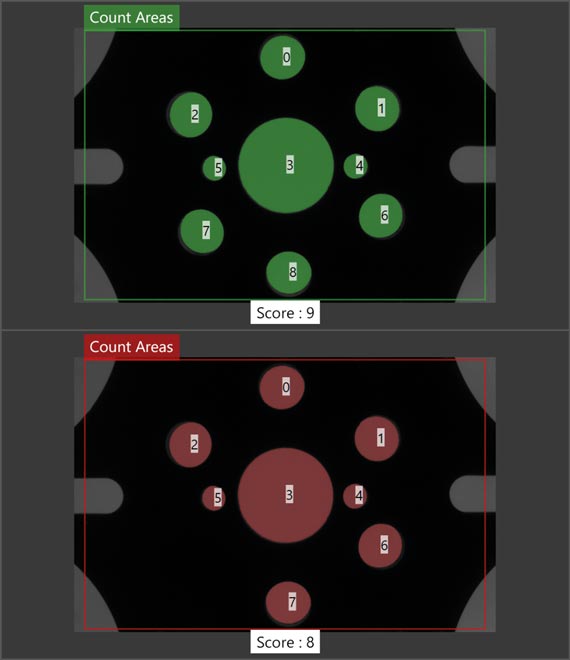

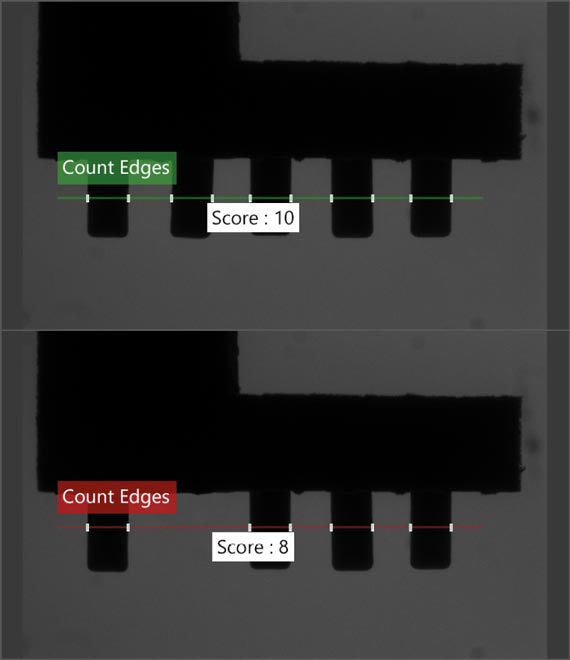

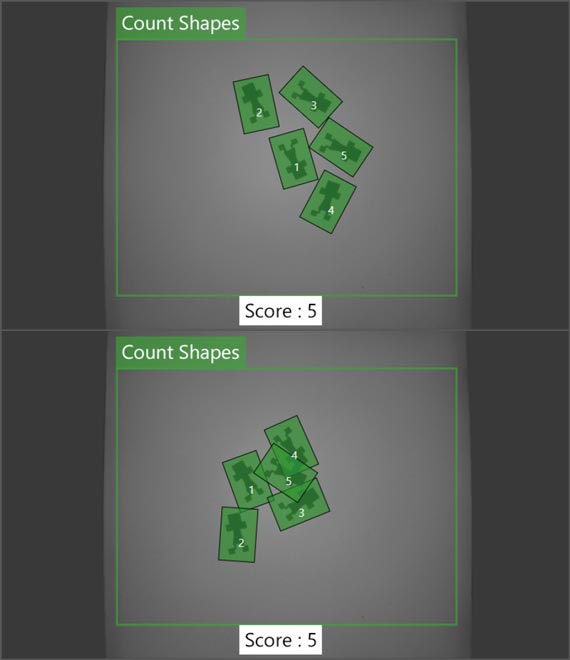

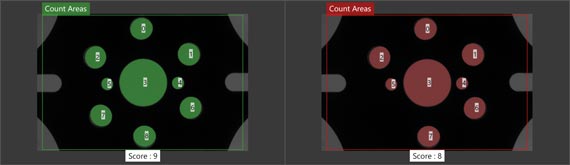

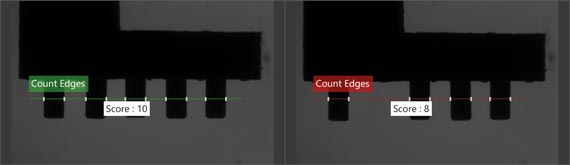

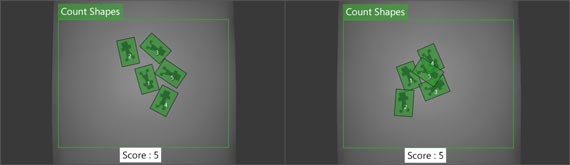

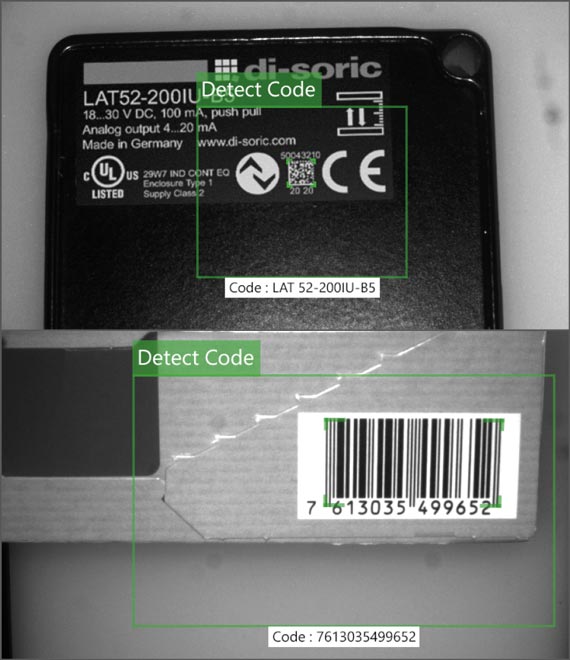

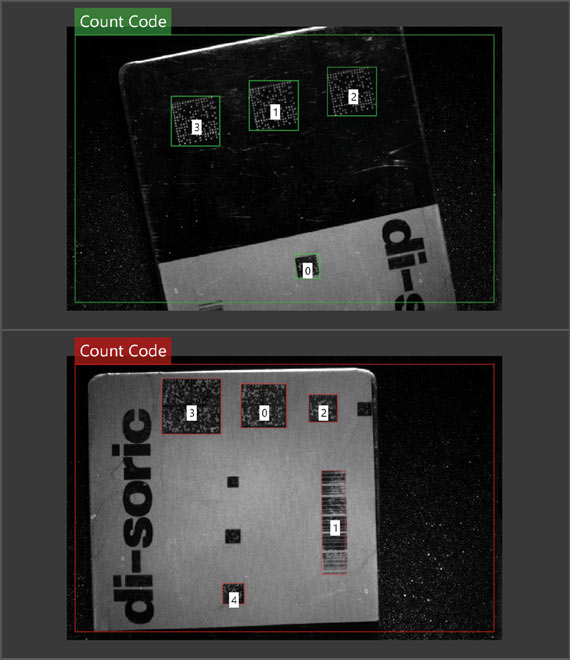

Counting of areas, edges and shapes

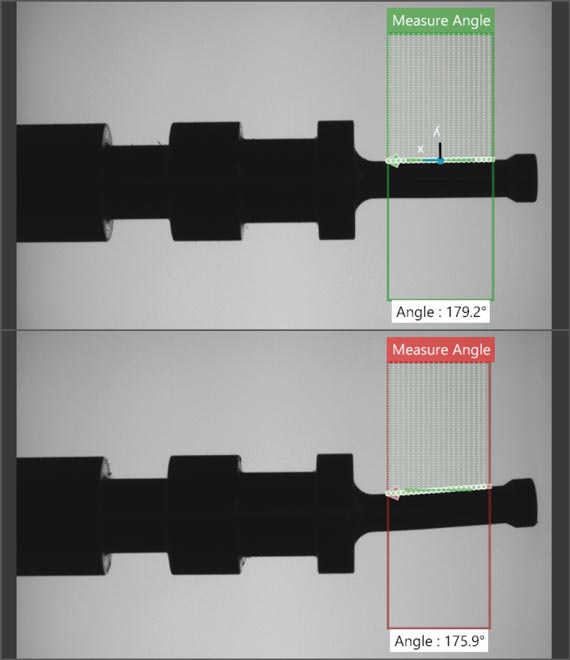

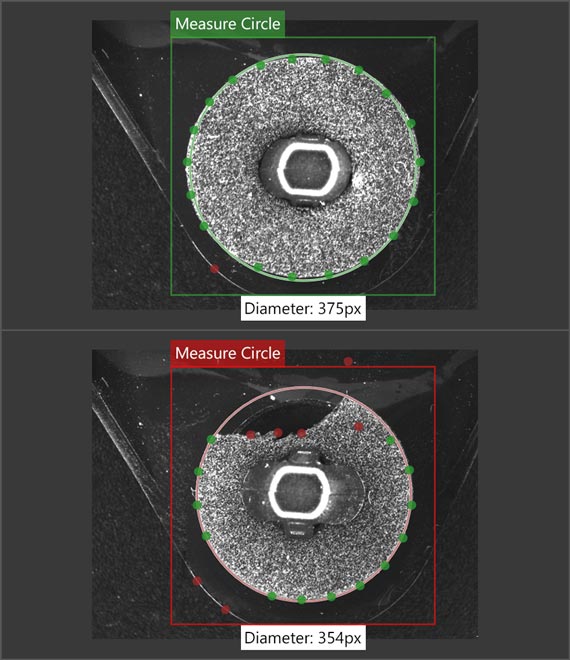

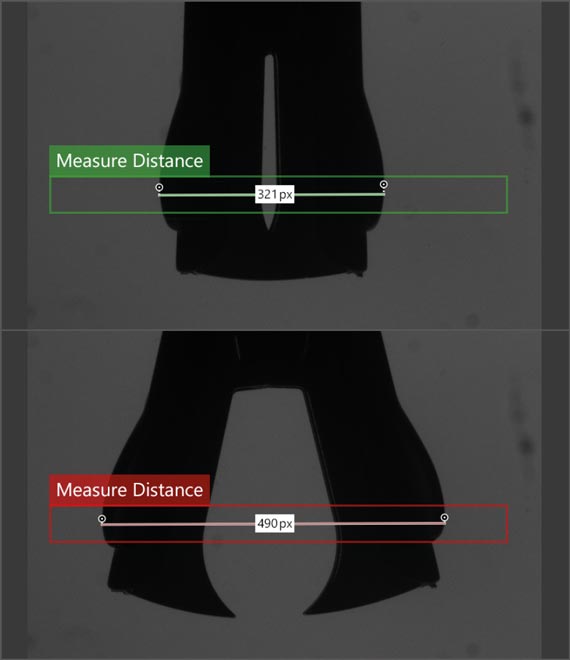

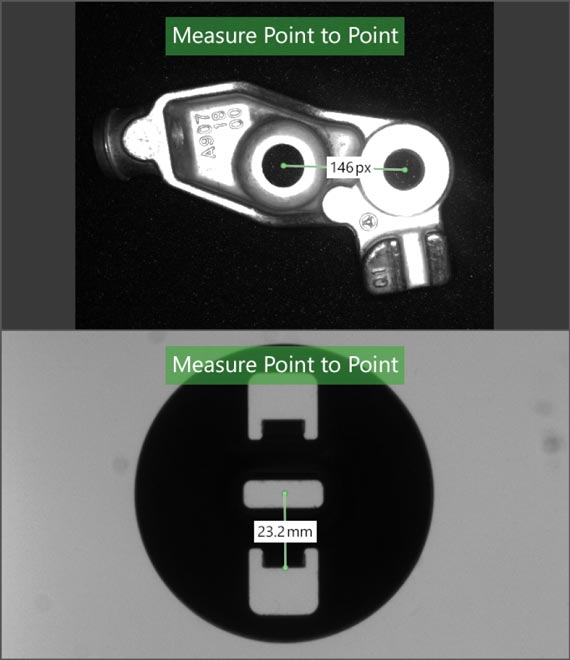

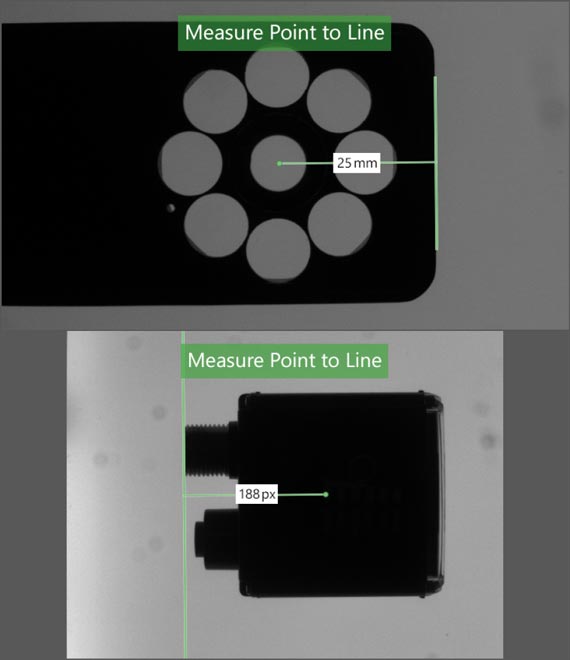

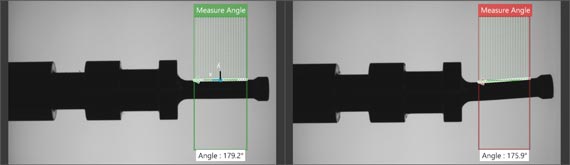

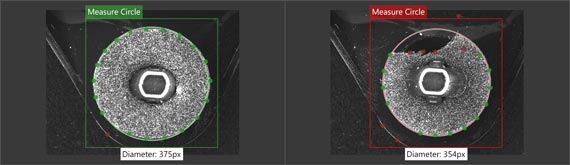

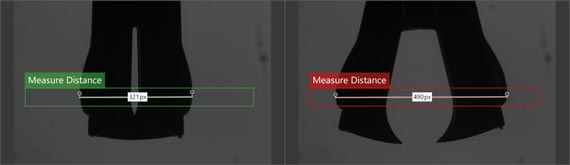

Measurement of angles, diameters, distances and spacings in mm and pixels (Upgrade)

Locate and read 1D and 2D codes (Upgrade)

Locate Code

Finds a code within the defined search field and serves as a guide for subsequent tools – efficient for label fit check

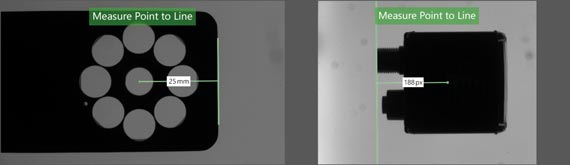

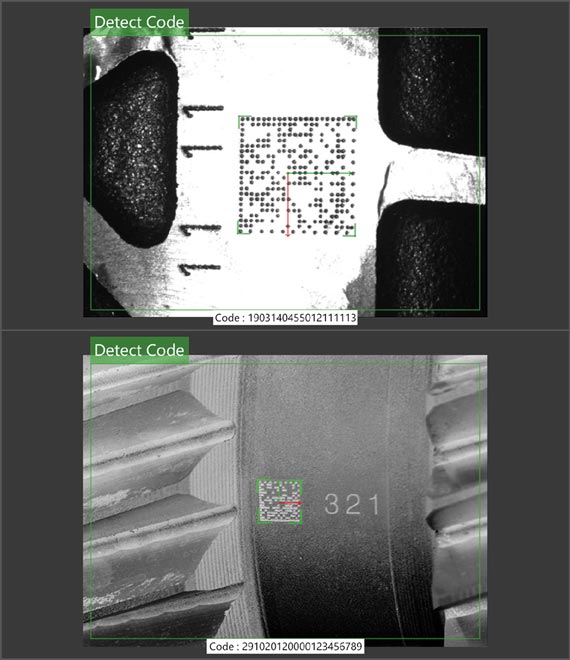

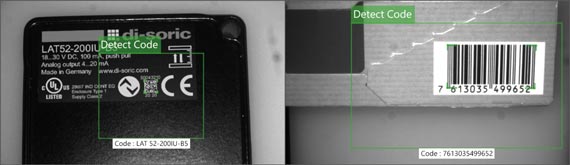

Detect Code

Decodes all codes and can evaluate the content using different criteria (regular expressions)

Tools for ID Readers ID-600

Locate and read 1D and 2D codes

Locate Code

Finds a code within the defined search field and serves as a guide for subsequent tools – efficient for label fit check

Detect Code

Decodes all codes and can evaluate the content using different criteria (regular expressions)

Read directly marked codes (DPM) on difficult surfaces (Upgrade)

nVision-i

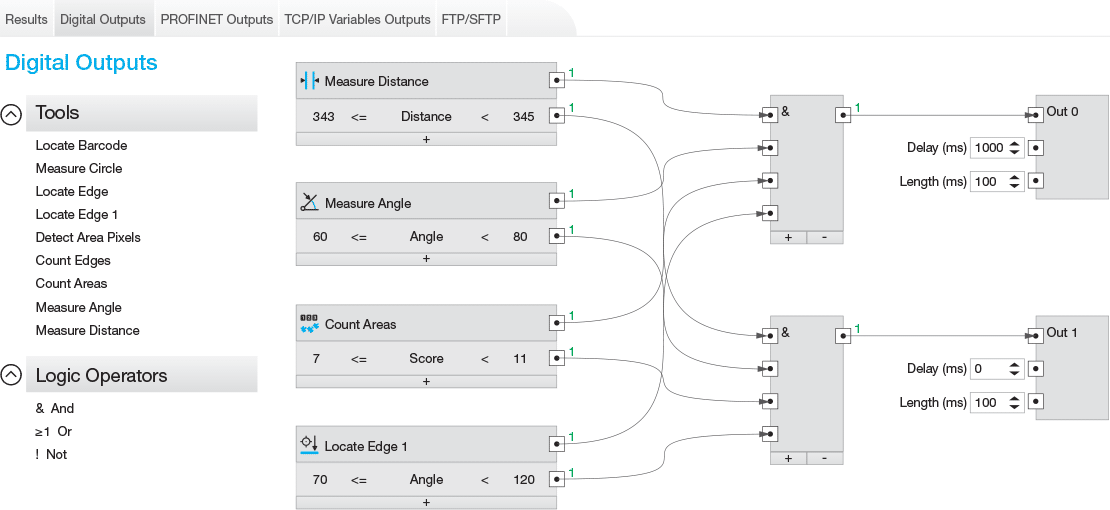

The Logic tool

The linking of results to outputs

Through the free linking of the results of several tools into an overall result directly in the Vision Sensor you get a high-performance – without PLC load.

Another advantage is the high degree of flexibility:

the measured values or results can be addressed at any point on the Profinet field bus.

Short familiarization, no training required

The graphic-oriented Logic tool is based on a function plan (FBD), which enables a clear representation even for more complex functions. This in turn enables a simple and easily comprehensible implementation of the behavior of the inputs and outputs.

This eliminates the need for training, since the procedure is already familiar from the daily handling of PLC programming.

nVision-i

Image correction and calibration

Integrated image optimization

With 2 clicks, distortions and shadowing to the edge of the image can be easily eliminated by calibration via nVision-i.

The CS-60 vision sensors and ID readers ID-600 thus have the ability to reliably perform all detections over the entire field of view – the CS-60 can additionally convert pixel values into exact real values (mm) and output them.

In addition, both the vision sensors and the ID readers meet the requirements for those areas where flexibility, easy configurability and fast changeovers are paramount.

nVision-i Download

Software download and license

Download the nVision-i software in the download area on the detail page of a CS-60 or ID-600 and then activate it with the free nVision-i license.

nVision-i Upgrades

Choose what you need

nVision-i is not only intuitive and easy to use, but can also be individually adapted and extended to your application requirements through upgrades and customizing – so that CS-60 vision sensors and ID-600 ID readers always have the functions needed to solve your applications.